Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Advantages and System Characteristics:

a) Iron melt contains a significant amount of reducing elements such as silicon, carbon, and manganese, which results in low burnout and high utilization efficiency of desulfurizers during desulfurization, facilitating the process.

b) The presence of carbon and silicon in iron melt significantly enhances the activity coefficient of sulfur, improving the thermodynamic conditions for desulfurization and enabling the removal of sulfur to a lower level.

c) The low oxygen content in iron melt increases the sulfur distribution coefficient between slag and iron, which is beneficial for desulfurization.

d) The relatively low treatment temperature of iron melt prolongs the lifespan of refractory materials and processing equipment.

e) The cost of desulfurizing iron melt is lower compared to desulfurization in blast furnaces, converters, or secondary refining facilities. For instance, the cost of removing one kilogram of sulfur in a blast furnace, converter, or secondary refining facility is 2.6, 16.9, and 6.1 times higher, respectively, than that in iron melt desulfurization.

f) Changes in iron melt composition during external desulfurization have less impact on the final steel composition compared to changes during steelmaking or secondary steel treatment.

g) Adopting iron melt desulfurization not only reduces the burden on blast furnaces, decreases coke ratio, and improves productivity by reducing slag volume, but also enables converters to operate without the need for high slag volume and high basicity for desulfurization, as desulfurization under the highly oxidative slag conditions in converters is quite challenging. Consequently, iron melt desulfurization has become a crucial means to optimize production processes in modern steel industries, enhancing steel quality and expanding product ranges.

Process Flow:

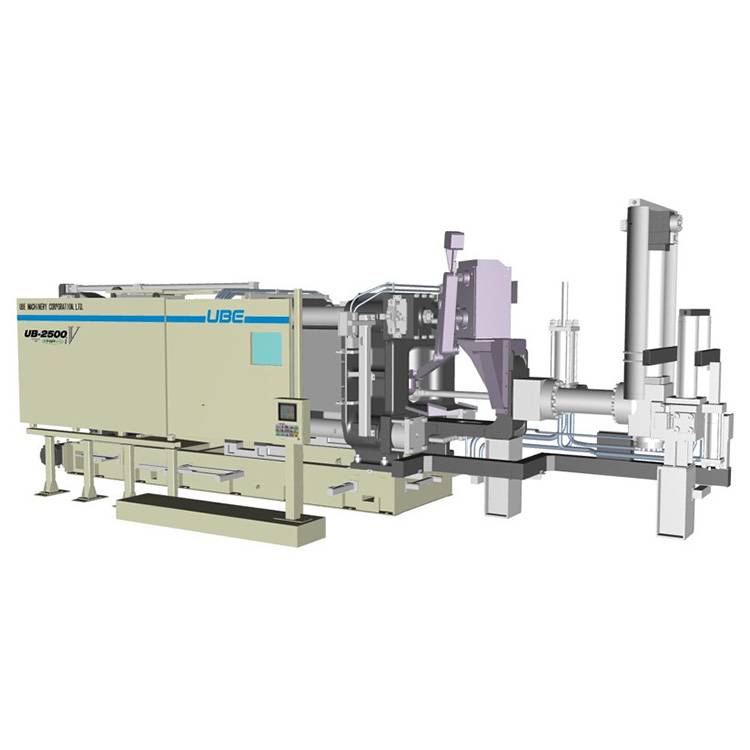

The iron melt desulfurization system typically comprises an iron melt transportation and tilting system, an injection system (single-injection of particulate magnesium), a slag skimming system, a dust removal system, a material feeding system, and an automatic control system.

Introduction to the Process Model:

The objective of the process model is to ensure smooth operation during the injection process, using the minimum amount of magnesium-based desulfurizer to achieve the target sulfur level. The consumption of magnesium-based desulfurizer is influenced by over a dozen factors. In practical industrial operations, only five primary variables are input into the process model: initial sulfur content in iron melt, initial temperature of iron melt, amount of iron melt to be processed, target sulfur level, and metallic magnesium content in particulate magnesium. Based on these inputs, the process model calculates the magnesium injection rate at different time intervals, the carrier gas flow rate at different time intervals, total magnesium injection time, total consumption of magnesium-based desulfurizer, and stores these values in the computer. Additionally, these values are displayed on an LCD screen. The magnesium injection rate is controlled by adjusting the frequency of the variable-frequency motor driving the rotor feeder via the computer. The carrier gas flow rate is regulated by adjusting the opening of the flow control valve, which is matched with a high-precision flowmeter. For added flexibility in process operation, under automatic mode, the magnesium injection rate, carrier gas flow rate, and initial sulfur content can be manually adjusted. When the magnesium injection rate is manually adjusted, it can be set within 412 kg/min, resulting in a corresponding change in total magnesium injection time. Similarly, when the carrier gas flow rate is manually adjusted within 30170 Nm³/h, it and the total consumption of magnesium-based desulfurizer will vary accordingly.

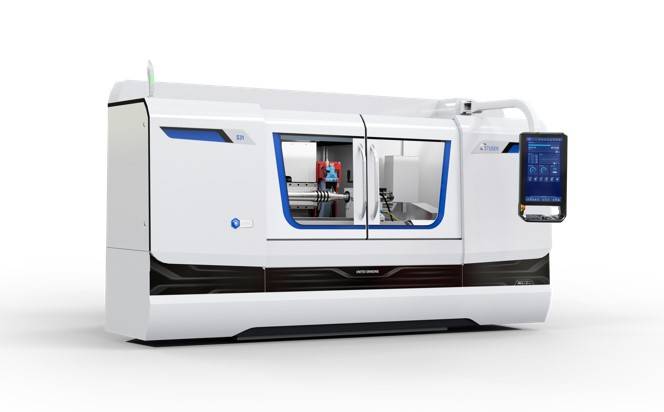

Automation Control System:

a) The automation control system fully meets all requirements of the process, ensuring reliable operation and leveraging cutting-edge technologies.

b) To accomplish a series of automation tasks, the single-injection particulate magnesium iron melt desulfurization plant adopts a PLC from Siemens.

c) The automation control system of the iron melt desulfurization plant can communicate with other factory control systems (such as the secondary and tertiary systems of the steelmaking system) via its built-in Microsoft SQL Server database.

Search

Search