Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

In recent years, in order to cope with a variety of products, the crankshaft production line requires a more flexible production system.

The 821LAMC is a crankshaft balancing machine for passenger cars and was developed to meet the flexibility requirements of the crankshaft production line.

The 821LAMC can fully automate measurement, correction and inspection in a small setup space. In addition, due to the small footprint, the design arrangement of the mass production line has more freedom.

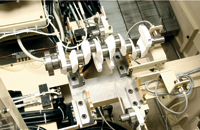

Measuring station

The workpiece is moved to the measuring station by the in-machine loader, and the crankshaft is rotated by the friction drive of the ultra-hard roller. The in-line 3-cylinder crankshaft is supported by the No.1,4 spindle neck, and the in-line 4-cylinder crankshaft is balanced by the No.1,5 spindle neck. No counterweight measurement is possible for 3-cylinder asymmetric crankshafts, thus making it possible to randomly produce 4-cylinder crankshafts and 3-cylinder crankshafts.

Correction station

At the correction station, the unbalance is corrected by a set of shaft drilling device driven by NC control. The borehole depth required to correct the unbalance is calculated by a special measuring device.

Detection and measurement

The crankshaft after the corrected blow cleaning procedure is placed on the measuring device for a balanced re-measurement to determine OK /NG.

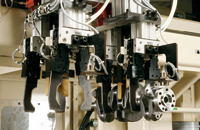

Internal loader (double arm manipulator)

Internal handling loader (Double arm manipulator)

The machine handling manipulator is responsible for the handling of the crankshaft between various stations.

Due to the use of double-arm manipulator, the handling speed is greatly improved.

Measuring device

Microprocessor measuring device MMi-902C

It is composed of a touch screen industrial computer and a measurement computing device equipped with a color TFT screen.

Various mechanical Settings are performed through touch screen operation. Because of its self-diagnosis function and modular form, the equipment has excellent maintenance.

![[Second-hand] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search