Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Precision computer-controlled hot chamber die-casting machine

Product features:

1. Maximum air injection velocity ≥ 5m/s;

2. Standard design, excellent performance, equipped with piston type energy storage;

3. Adopting a hydraulic gear mold adjustment mechanism, the mold adjustment is smooth;

4. Adopting high rigidity design templates and machine hinges;

5. The machine hinge is equipped with an automatic central lubrication system, which independently adjusts the lubrication cycle and oil volume, improving the mechanical life and operational reliability.

6. Carefully designed die-casting control system, suitable for high-quality die-casting;

7. Adopting a unique dual proportional hydraulic system to save energy and improve production efficiency;

8. The unique express mold locking system increases production efficiency.

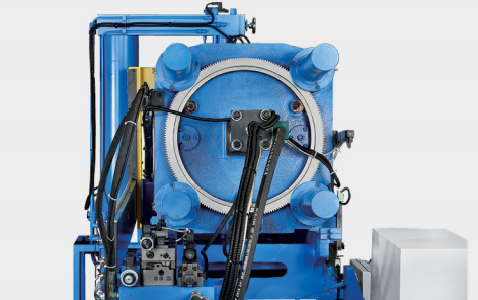

Fast and precise mold adjustment system

Main features:

1. Hyperbolic axis machine hinge locking structure, high-strength ductile iron template processed with CNC precision, sturdy and durable;

2. Wear resistant hard chromium high tensile alloy steel guide column, durable and reliable;

3. Low voltage protection program to ensure mold safety;

4. High precision electronic ruler position detection, precise control of mold locking stroke;

5. Automatic front and rear movement tilting locking system, with options for fixed mouth and off mouth die casting;

6. Large mold space for fully automatic adjustment of mold thickness;

7. Equipped with oil pressure automatic lifting mold seat function, the center or offset injection position can be selected;

8. The computer and oil circuit work together to achieve four stage mold locking, ensuring that the low-pressure mold locking stage plays a protective role and effectively protects the template and mold.

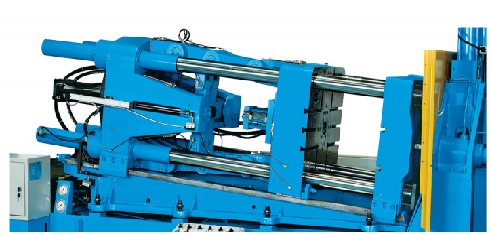

Stable and reliable injection system

Product features:

1. Adopting a piston type energy storage device and a crossbeam injection system, it achieves fast filling, long service life, stable use, and easy maintenance.

2. The original new concept of dual speed injection oil circuit design, in which the slow speed injection adopts proportional control and can be CNC adjusted for speed, is suitable for producing all high-quality die-casting parts;

3. Advanced injection system achieves stable and effective injection speed, with an air injection speed of 5m/s or more;

4. The furnace adopts digital temperature control, and the temperature of the molten material can be accurately adjusted to maintain stable production and extend the life of the hot work parts.

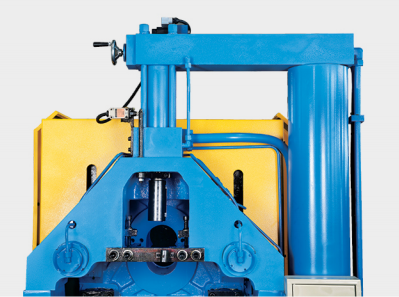

Fast and precise mold adjustment system

Product features:

1. Adopting a hydraulic gear mold adjustment structure, the operation is simple and the mold adjustment is smooth;

2. Intelligent automatic mold adjustment system, precise calculation of mold position, convenient mold replacement, and improved efficiency

Advanced Control System

Electrical control part:

1. Equipped with two types of electrical boxes: integral and independent, making it convenient for users to choose and arrange;

2. Artificial intelligence computer control can control and monitor the action data and status of each action, facilitating operation and maintenance;

3. Large screen LCD display with language conversion between Chinese and English;

4. Powerful memory function, capable of storing 120 sets of mold forming data, such as time, frequency, speed, pressure, stroke, mold thickness, selection conditions, etc;

5. Equipped with computer hardware fault self-test alarm function and mechanical fault alarm display function, it is easy to troubleshoot machine faults;

6. Input and output inspection function, equipped with LED light display;

7. The locking mold adopts high-precision electronic ruler positioning detection, and the position monitoring accuracy can reach 0.1mm;

8. Automatically record production time and batch size, set batch size for forming quantity, and allocate automatic shutdown.

Search

Search