Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Standard precision cold chamber die-casting machine

Product features:

1. The injection mechanism adopts a rod structure combined with a hydraulic lifting device, which is widely applicable to mold requirements;

2. The carefully designed injection system adopts independent high-quality piston type rapid and pressurized energy storage devices;

3. The use of large-diameter logic valves and precision flow control valves improves injection response and reduces oil pressure oscillations, and provides precise four stage injection adjustment with a wide range of injection parameters and strong adaptability;

4. Adopting a hydraulic gear adjustment mechanism, it is easy to operate and accurately adjusts the high tensile strength of the guide column;

5. Unique fast mold locking system for higher production efficiency;

6. The machine hinge is equipped with an automatic central lubrication system, which can independently adjust the lubrication cycle and oil amount, improving the mechanical life and operational reliability.

7. The hydraulic system adopts a high-performance, energy-saving high-low dual pump control system, which saves energy and improves production efficiency.

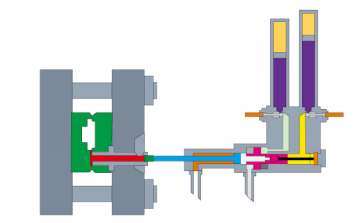

Injection: A stable high-performance injection system

Product features:

1. Adopting a unique vibration force injection system, the injection is more powerful, greatly improving the stability of product quality;

2. The injection and boost energy storage devices are independently separated, and the injection is independently regulated to ensure the stability of the injection pressure;

3. The injection adopts a four rod structure, which is more stable and reliable;

4. The maximum air injection velocity is ≥ 8m/s, and the pressurization and pressure building time is ≤ 20m/s.

Low speed range: precise control can be achieved to avoid air entrapment and gas accumulation issues;

High speed section: can quickly reach the highway, effectively controlling the filling time and casting forming effect;

Boosting section: The boosting speed can be changed according to the process to enhance the density of the casting without causing deformation.

Locking: Durable and efficient locking structure

Product features:

1. Double curved elbow machine hinge locking structure, high-strength ductile iron template with CNC precision machining, sturdy and durable;

2. High tensile alloy steel guide column, durable and reliable;

3. High precision electronic ruler position first detection, precise control of mold locking stroke;

4. Mechanical elbow automatic lubrication improves wear resistance;

5. The hydraulic gear adjustment mechanism is stable;

6. Independently adjustable mold backup pressure system (customization required).

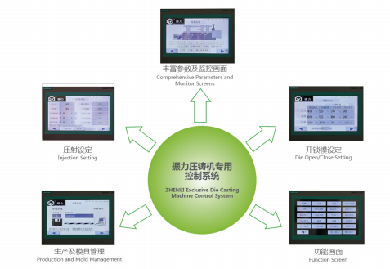

Control: A fully functional die-casting control system

Product features:

1. Adopting Siemens S-7 200 artificial intelligence control system, it can control and monitor the data and status of each action;

2. Large screen LCD display, capable of converting multiple languages such as Chinese, English, Russian, Portuguese, etc;

3. Powerful memory function, capable of storing mold forming data such as time, parameters, speed, pressure, stroke, mold thickness, selection conditions, etc;

4. It has the functions of self checking and reporting computer hardware faults, as well as displaying mechanical fault alarms, making it easy to troubleshoot machine malfunctions;

5. The locking mold adopts high-precision electronic ruler positioning detection, and the position control accuracy can reach 0.1mm.

Search

Search