Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

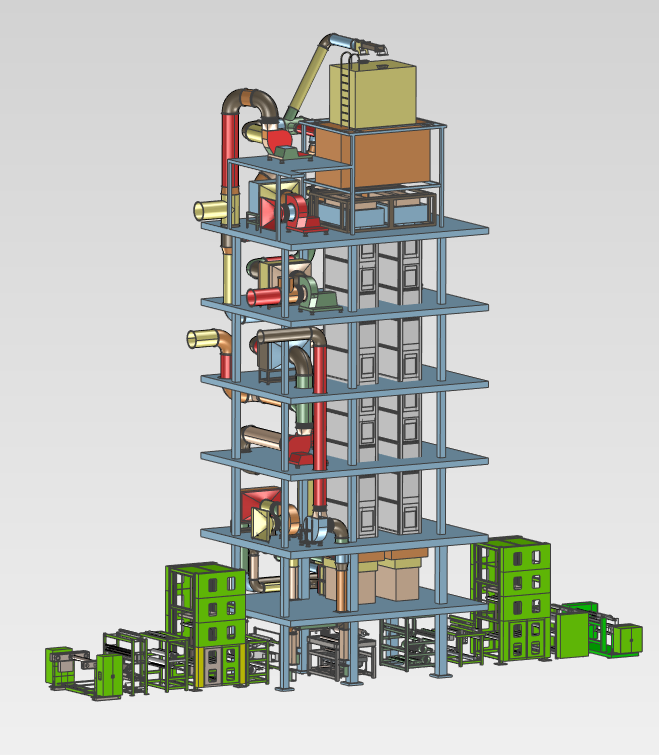

Patented Thermal Conduction Cooling (TCC)

Very suitable for evaporation of organic materials in ultra-high pressure and OLED applications

Fast and accurate temperature control with a temperature range of 15-300 ° C

UHV and MBE are fully compatible

Applicable to OME 40-2-25-S on DN40CF (outer diameter 2.75 ")

The organic material infiltration pool OME is specifically designed for evaporating or sublimating high vapor pressure materials, especially sensitive organic substances, at operating temperatures up to 300 ° C. It can also be used for other materials, typically evaporating at very low temperatures, such as alkali metals.

Due to its patented heat conduction cooling encapsulated heater unit, OME provides significantly improved operational performance below the temperature limit of the most common Knudsen type exudate cells. The new TCC concept involves liquid metal used as a thermal conductor, which provides a direct thermal connection between the crucible and the heat storage without leaving any isolation gaps.

Due to the T4 dependence of the emitted radiation power, traditional infiltration pools exhibit poor cooling efficiency, making precise temperature control below 150 ° C very difficult. In contrast, OME utilizes linear heat transfer between heated heat storage and cooled radiators, achieving high cooling rates even at very low operating temperatures. Thus achieving rapid cooling, low heat time constant, and stable temperature control.

OME cells exhibit excellent long-term temperature stability. During the 10 hour operation, the temperature will not exceed ± 0.02 K.

According to Stefan Boltzmann's law, the cooling rate of traditional infiltration batteries with thermal radiation cooling (TRC) increases with battery temperature, while the cooling rate of TCC batteries increases linearly with temperature. Despite the high thermal mass of TCC batteries, their cooling rate is much higher at low temperatures, reaching 10 ° C/minute even at a battery temperature of 70 ° C.

The comparison between the torque converter clutch unit and TRC unit during the cooling process is shown in the above figure. It shows the temperature drop of two batteries starting at the same battery temperature of 150 ° C. The cooling speed of the torque converter clutch unit is four times faster.

The heating and cooling time of OME is relatively short, and no temperature overshoot was found during the heating step. Its excellent low-temperature performance makes OME batteries very suitable for the evaporation of temperature sensitive materials such as organic compounds or polymers. Rapid heating and cooling rates can avoid wasting expensive materials during non operational time.

Organic evaporation source 1. png

Click to view more ‘Product Categories’

Direct to specific products: Molecular Beam Epitaxy (MBE), Pulsed Laser Deposition (PLD), Reflective High Energy Electron Diffraction (RHEED), Evaporation Source, Ion Source, Electron Gun

![[Used] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search