Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Precision electron beam welding equipment

Product Description:

The core component of our electron beam welding machine is MICROBEAM: a unique 2 kW electron generator with precise electron beam control capability. High precision control of the size, position, and power of the electron beam spot can optimize to achieve a very narrow process window, and the electron beam spot can be adjusted between 25 µ m or more than 1 mm.

The three pole structure electron gun can achieve particularly precise control of the electron beam. Using directly heated tungsten cathodes (needles or ribbon filaments) or LaB6 cathodes to form electron beams with axial symmetry and minimal cross effects.

The high-voltage power supply provides a continuously adjustable voltage of 5 to 60kV (with a minimum step size of 20V), and the electron beam current ranges from 15 µ A to 33 mA (with a minimum step size of 10 µ A). Combined with pulse working mode, it can solve the most demanding process window problems.

The standard precision electron beam welding machine provided by FOCUS can be used for various welding tasks. All machines are equipped with MICROBEAM generators. Our MICROBEAM generator can also be purchased separately as a component to upgrade your existing electron beam welding machine.

POWERBEAM L135

Universal models with a wide range of applications. Larger working chamber and movable electron gun.

Square cavity with a volume of 135 liters. The size is 500 × 500 × 540 mm3

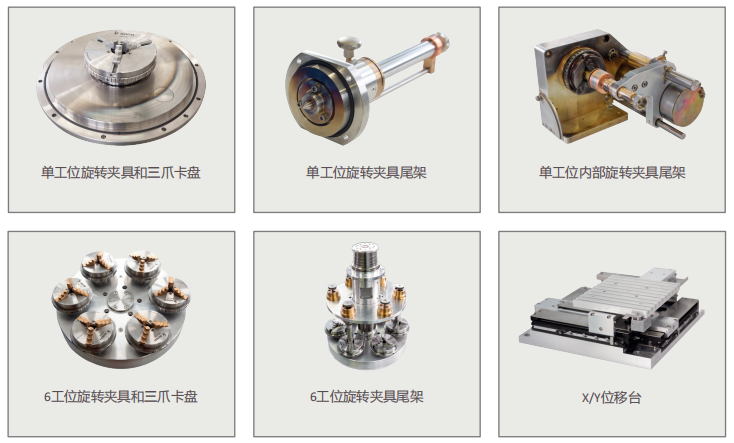

Equipped with an X/Y CNC displacement table with a displacement stroke of ± 75 mm, it can be equipped with a single or drum type rotating fixture (installed horizontally or vertically during class)

CNC linear displacement electron gun with a stroke of 160 mm

• Floor area of 2 × 2.9 m, adjustable

Our standard models are capable of handling most welding tasks. We can also customize and develop welding machines for special tasks according to customer needs.

Examples of application areas

▶ Sensor casing

Accurate control of electron beam spot and power is a prerequisite for precise welding of sensors. Any small change in welding parameters may have a significant impact on the performance of the final product

Welding in a vacuum environment can provide vacuum sealed welds without the need for additional vacuuming operations

Can weld various similar and different materials, including copper, aluminum, titanium, stainless steel, tantalum, zirconium, niobium, molybdenum, tungsten, etc

▶ Aerospace industry

The aerospace industry is using precision electron beam welding to produce aerospace components, spacecraft (such as rockets and satellites), and defense systems

Durable, reliable, and vacuum sealed light alloy metal connections

Various sensors, accelerometers, turbine blades, fuel injectors

Our POWERBEAM machines are equipped with advanced features that enable our customers to achieve high-quality welds with minimal heat generation and distortion. FOCUS can weld a wide range of materials, including metals, alloys, semiconductors, various materials of different thicknesses and complex geometries.

▶ Nuclear industry

Electron beam welding is the preferred and validated technology in the nuclear industry, which is applied due to its ability to produce high-quality and precise welds

Welding fuel rods to end caps to manufacture nuclear fuel assemblies

Manufacturing various reactor components, such as pressure vessels, steam generators, and heat exchangers

▶ research and development

Open system architecture with innovative ideas

• Compact size, compatible with laboratories and cleanrooms

SEM mode, observation window or optical CCD camera for easy observation of all processes

• It is easy to add measuring instruments

Very flexible in terms of parameter range and workpiece size

• Can generate almost any thermal field, thermal gradient, or alter local surfaces on the sample

Workpiece table

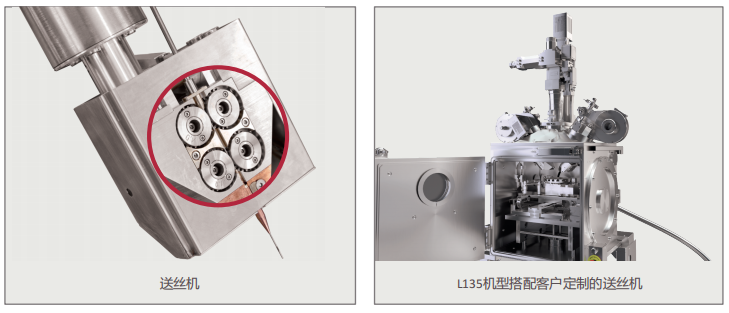

Different workpiece fixtures and heat dissipation solutions are key to achieving excellent results in precision electron beam welding. We provide both standard solutions and develop unique fixtures according to customer requirements.

More possibilities

In addition to traditional electron beam welding tasks, FOCUS also offers surface modification solutions. Accurate energy transfer can finely control the melting process of wires or powders.

![[Second-hand] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search