Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Product Description:

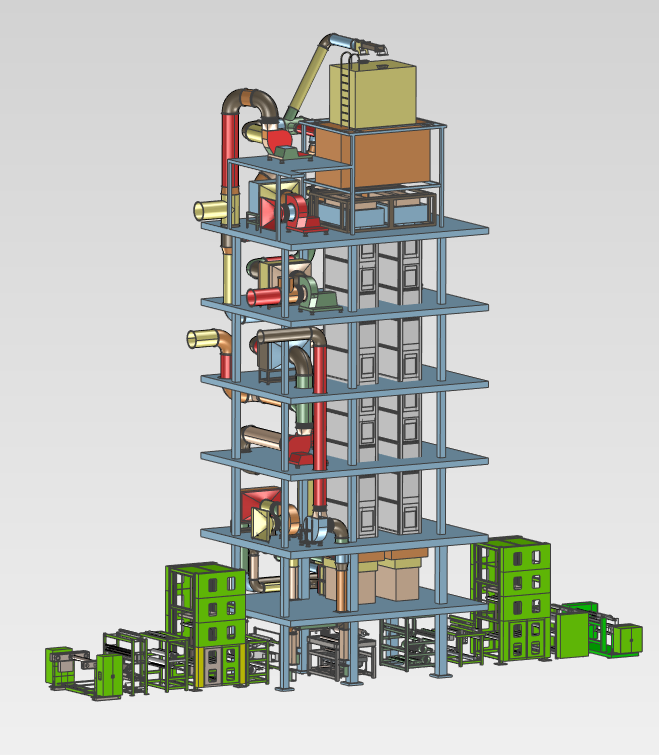

FOCUS's LaVa (vacuum internal laser welding) series models are all integrated welding solutions. All LaVa models are integrated with OptiShield ® The system is used to protect the laser entrance window from contamination, and also integrates a complete CNC control system for controlling the laser and workpiece. This series of products includes LaVa L135, LaVa L8, LaVa L95

LaVa L135

Universal models with a wide range of applications, larger working chambers, and movable laser beams.

Laser power: 500 W to a maximum of 6 kW

Square cavity: with a volume of 135 liters and dimensions of 500 × 500 × 540 mm ³

Equipped with an X/Y CNC displacement table with a displacement stroke of ± 75 mm, it can be equipped with a single or drum type rotating fixture (installed horizontally or vertically)

CNC linear displacement laser beam with a stroke of 160 mm

• Covering an area of 2.3 × 3.9 m, adjustable

We can also customize welding machines with laser power ranging from 500 W to up to 16 kW according to customer needs. In addition, customized models can also be equipped with various analytical sensors according to needs.

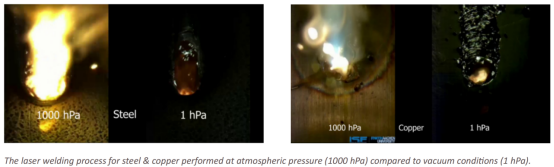

Comparison of laser welding processes for stainless steel and copper at different pressures (atmospheric pressure and 100 Pa)

Technical Introduction

The use of lasers in vacuum has expanded the scope of traditional laser welding. This technology is suitable for:

Engineers facing physical limitations of existing laser welding systems.

Engineers who hope to use laser welding instead of electron beam welding. The choice of ideal welding technology is mainly determined by the material of the workpiece.

The FOCUS LaVa system brings the power of laser welding into a vacuum environment, enabling ultra clean and deep penetration during welding (which can be achieved at lower temperatures compared to atmospheric environments). Due to the fact that the boiling point of materials depends on pressure, in order to achieve the same welding effect, laser welding under vacuum conditions may have a welding temperature 1000 ℃ lower than welding under atmospheric conditions! Low temperature welding limits heat circulation and reduces workpiece distortion, while also minimizing bubbles due to stable weld hole formation. Depending on the laser model and specific configuration, a spot with a diameter of 50 μ m or smaller can be achieved.

In addition to all the advantages of laser welding, the vacuum environment also adds the following benefits:

Significantly reduce welding holes and minimize spatter

● Increase penetration depth by at least twice

No X-rays are generated, no X-ray protection device is required

● Fast and accurate beam oscillation and deflection can be achieved through optical systems

Suitable for al* all metals (including refractory materials), metal pairs, and certain plastics and ceramics

The welding area does not require protective gas

Not affected by magnetic fields

Stable formation of welding holes (similar to electron beam welding)

Comparison of welding results of stainless steel under atmospheric pressure and vacuum degree of 1 mbar

The use of lasers in vacuum has expanded the scope of traditional laser welding. This technology is suitable for:

Engineers facing physical limitations of existing laser welding systems.

Engineers who hope to use laser welding instead of electron beam welding. The choice of ideal welding technology is mainly determined by the material of the workpiece.

The FOCUS LaVa system brings the power of laser welding into a vacuum environment, enabling ultra clean and deep penetration during welding (which can be achieved at lower temperatures compared to atmospheric environments). Due to the fact that the boiling point of materials depends on pressure, in order to achieve the same welding effect, laser welding under vacuum conditions may have a welding temperature 1000 ℃ lower than welding under atmospheric conditions! Low temperature welding limits heat circulation and reduces workpiece distortion, while also minimizing bubbles due to stable weld hole formation. Depending on the laser model and specific configuration, a spot with a diameter of 50 μ m or smaller can be achieved.

In addition to all the advantages of laser welding, the vacuum environment also adds the following benefits:

Significantly reduce welding holes and minimize spatter.

The penetration depth should be increased by at least twice.

No X-rays are generated, and X-ray protection devices are not required.

Fast and precise beam oscillation and deflection can be achieved through optical systems.

Suitable for al* all metals (including refractory materials), metal pairs, and certain plastics and ceramics.

The welding area does not require protective gas.

Not affected by magnetic fields.

Stable formation of welding holes (similar to electron beam welding).

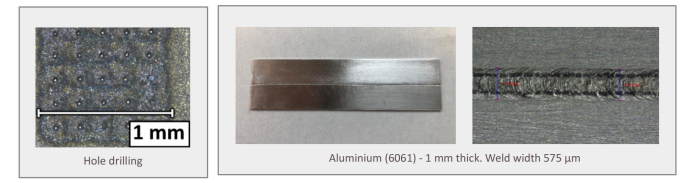

Perforated aluminum sheet (6061) welding - thickness 1 mm, weld width 575 μ m

Copper sheet welding - welding of martensitic steel with a thickness of 0.5 mm and a welding width of 405 μ m

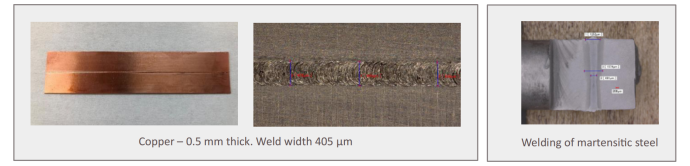

Workpiece table

Different workpiece fixtures and heat dissipation solutions are key to achieving excellent results in vacuum laser welding. We provide both standard solutions and develop unique fixtures according to customer requirements.

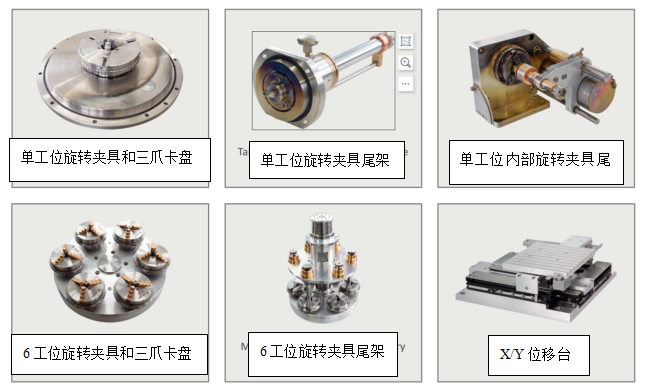

More possibilities

In addition to traditional electron beam welding tasks, FOCUS also offers surface modification solutions. Accurate energy transfer can finely control the melting process of wires or powders.

![[Used] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search