Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

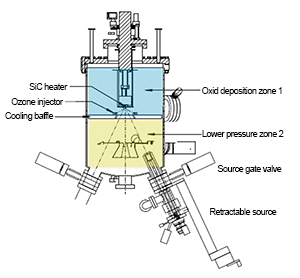

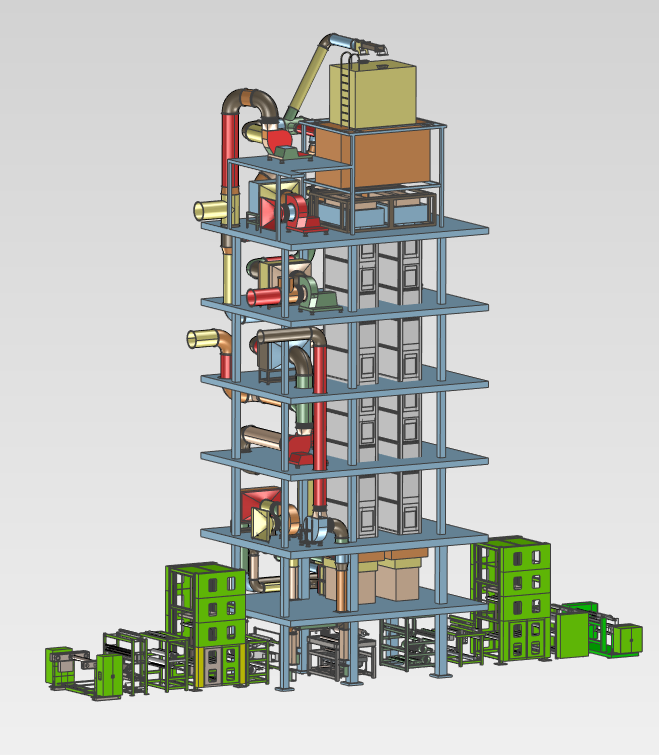

Molecular beam epitaxy system (MBE) OctoplUS-O-400 is an MBE system specifically designed for the growth of oxide films. The principle of differential pumping enables the heating source to grow oxide films in oxygen or ozone environment. Suitable for 2-inch wafers and small size samples under 2 inches. The vertical segmented cavity design can be equipped with various source furnages to realize molecular beam epitaxy growth of different materials.

Chamber size: 450 mm ID, liquid nitrogen cold screen (compatible with water cooling)

Background vacuum: < 2 × 10-10 mbar

Sample size: up to 2 inches, downward compatible with small size samples

Source furnace flange: 9 × DN63CF, up to 12

Design features: cavity differential design, ozone spray close to the substrate, source furnace separate differential pumping

Heater: anti-oxidant SiC heater, substrate temperature 850℃

Optional: CO2 laser heating, substrate temperature 1700℃

Application: Oxides

System features:

● Strong differential pumping, double pressure zone design

● Ozone-resistant SiC sample heater at high temperature

● Ozone jet ring designed near the sample table

● Concentrated or non-concentrated ozone sources

● In situ growth characterization

● Retractable source furnace design, no damage to vacuum refuelling

● 9 MBE evaporation source CF flanges, optional additional 3

● Compatible with multi-crucible electron beam evaporation

According to the requirements of all customers, we can provide different types of evaporation sources, including K-cell, electron beam evaporation source, thermal cracking source, valve cracking source, gas cracking source, etc. In situ monitoring of sample growth can be achieved using quartz crystal oscillator, reflective high energy electron diffractometer (RHEED) or quadrupole mass spectrometer.

OCTOPLUS-O 400 design description:

Area 1(blue)

● Oxide growing area

● Local high pressure for O2 and O3

● Ozone spray ring near the sample table, the distance between the spray ring and the sample is adjustable

● Low ozone depletion

● Ozone-resistant SiC heater at high temperature

● Strong differential pumping

Area 2(yellow)

● Evaporation source area

● Low pressure area formed by open holes leading to area 1

● Independent molecular pump

● Pressure significantly lower than zone 1

● Limited pass separator

● Differential pumping of each evaporation source is not required independently

● Multi-crucible electron beam evaporation can be integrated

For more information, click on the "Product categories "

Direct to specific products molecular beam epitaxy system (MBE), pulsed laser deposition system (PLD), reflective High energy electron diffractometer (RHEED), evaporation source, ion source , electron gun

![[Used] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search