Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

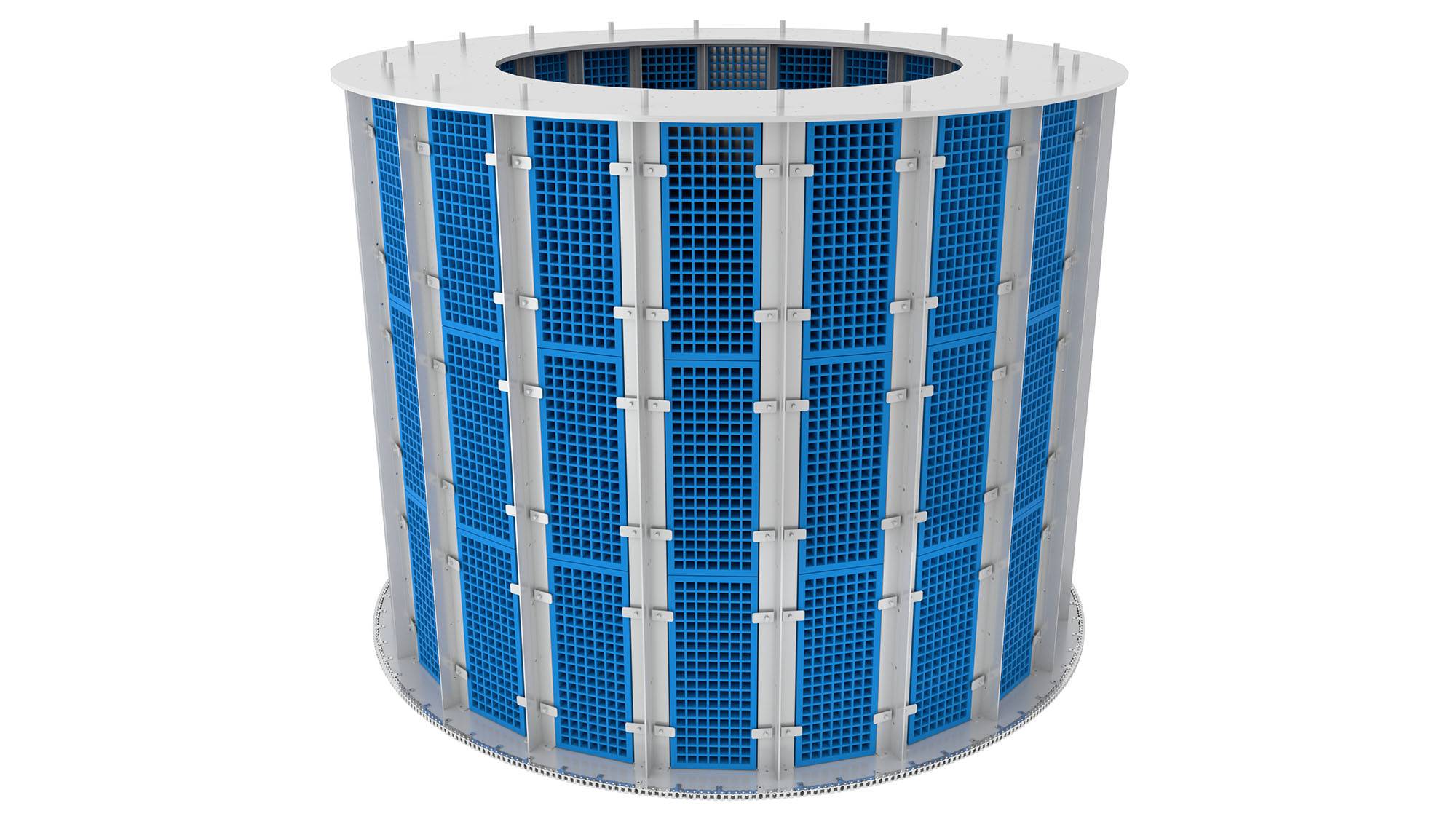

Industrial mine rotary dryer/limestone, clay, sand, water slag, slime, sludge, fly ash, gypsum powder, rock, petroleum coke barrel and other materials dryer.

Sand Dryer Drying Machine Product Advantages:

1. The sand dryer is made of alloy steel plate manufacturing,the wear-resisting 3-4 times of ordinary steel , the service life of the equipment is more than 10 years.

2. Material initial moisture content 15%, final moisture to ensure below 0.5-1%,which is the preferred products of the cement plant, GGBS and dry mortar production line.

3.The sand dryer thermal efficiency is as high as 80%, at the same time, the total power is low, 40% energy saving.

4.The fuel can be adapted to the coal, oil, gas,it can be dried under 20-40mm particles material, aggregate, powder material.

5.The sand dryer covers an area of about 40% lower than single drum dryer and civil investment reduced by about 50%.

6.No air leakage phenomenon, solved the sealing difficulties, modular units, installation is convenient.

7.The discharge temperature is < 50 ºC,which can be directly feed libraries, without cooling.

The sand is conveyed to the silo by belt conveyor or bucket elevator, and transported to the feed end by the feeder of the silo.The inclination of the feeding pipeline should exceed the natural inclination of materials to facilitate sand flowing into the dryer smoothly. The rotating cylinder of the dryer is slightly inclined to the horizon. Feed the material from the higher end and the heat carrier enters from the lower end, such produces adverse contact between them Sometimes, they can be fed to the cylinder together. As the cylinder runs, the sand is carried to the lower side by gravity. In the process of moving forward, the wet raw material is roasted by the heat directly or indirectly to make the raw material dry quickly, and the final products discharge out by belt conveyor or screw conveyor. There is a shoveling plate installed in the dryer with the function of shoveling the materials up and down, to enlarge the contact area between airflow and materials to enhance the efficiency and make the material run quickly. The heat carrier is hot air, the flue gas, etc. After the dryer process, It needs a cyclone dust collector to catch the items in the airflow. You should use a bag-type or wet-type dust collector and afterward discharge the waste gas if you intend to further reduce the dust load of the exhaust.

Search

Search