Post Requirements

Post Requirements Post Requirements

Post RequirementsProduct information

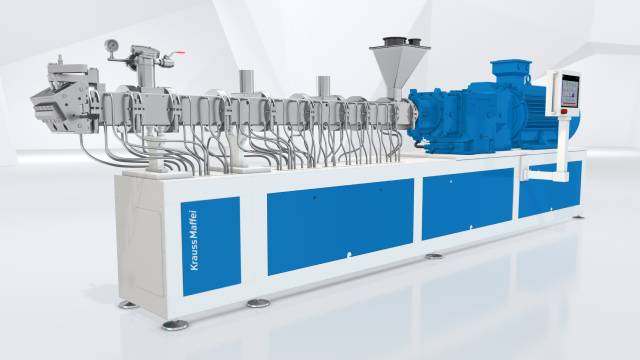

Product Introduction

Disc continuous dryer is an efficient conductive continuous drying equipment. Its unique structure and working principle determine its high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, and good operating environment. It is widely used in drying operations in industries such as chemical, pharmaceutical, pesticide, food, feed, and agricultural and sideline product processing. Highly praised in practical applications across various industries. We currently produce three types of products: atmospheric pressure, sealed, and vacuum, with four types: 1200, 1500, 2200, and 3000. A (carbon steel), B (stainless steel uniformly distributed in the contact material part), and C (on the basis of B, stainless steel is added to the steam pipeline, main shaft, and bracket, and stainless steel is lined inside the cylinder and cover). Three types of materials, with a drying area of 4-180 square meters, a series of hundreds of models of products, and can provide matching auxiliary equipment to meet the needs of users for drying various materials.

working principle

The wet material is continuously added to the first layer of drying disc on the upper part of the dryer by the feeder, and the rake arm with rake blades rotates to make the rake arm rotate and make the rake blades continuously flip the material. The material flows along an exponential spiral over the surface of the drying disc, and the material on the small drying disc is transferred to the outer edge, where it falls onto the outer edge of the large drying disc below. The material moves inward on the large drying disc and falls into the next layer of small drying disc from the middle discharge port. The drying plates of different sizes are arranged alternately up and down, allowing the material to flow continuously through the entire dryer. A hollow drying tray is filled with heating medium, which includes saturated steam, hot water, and thermal oil. The heating medium enters from one end of the drying tray and exits from the other end. The dried material falls from the last layer of the drying tray to the bottom of the shell, and is finally transferred by the rake blades to the discharge port for discharge. Moisture escapes from the material and is discharged through the dehumidification port located on the top cover. The moisture in the vacuum disc dryer is discharged through the vacuum pump port located on the top cover. Dry materials discharged from the bottom layer can be directly packaged. By adding auxiliary equipment such as fin heaters, solvent recovery condensers, bag filters, dry material mixing mechanisms, and induced draft fans, the production capacity of drying can be improved. Drying paste like and heat sensitive materials can facilitate solvent recovery and enable pyrolysis and reaction operations.

Adapt to materials

Drying, pyrolysis, combustion, cooling, reaction, sublimation

◎ Organic chemical products ◎ Inorganic chemical products ◎ Medicine and food ◎ Feed and fertilizer

Search

Search