Post Requirements

Post Requirements Post Requirements

Post RequirementsProduct information

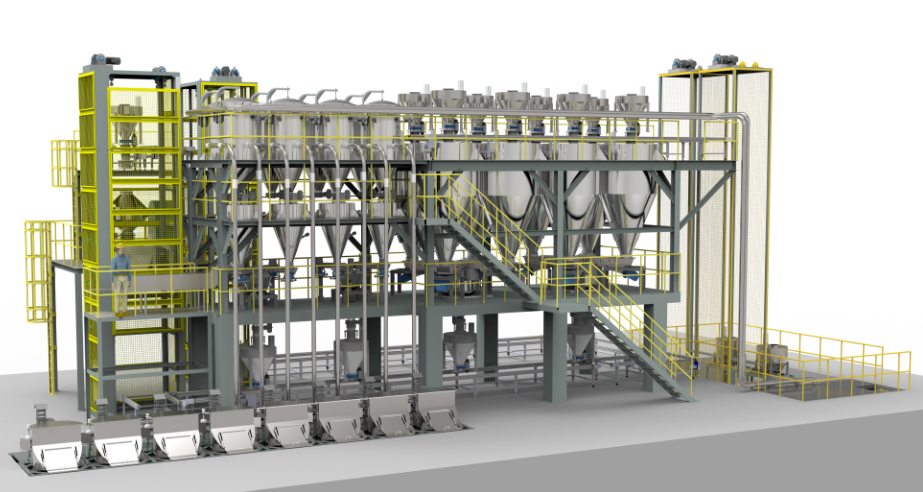

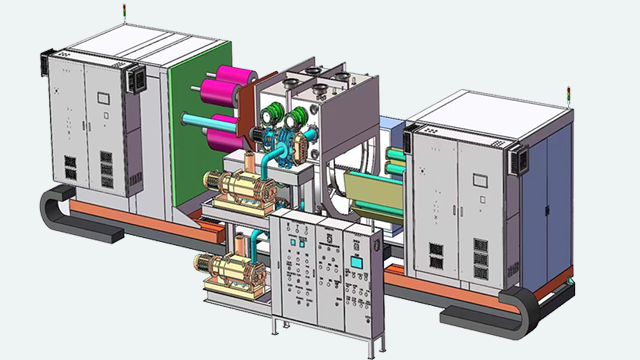

SHJ SERIES TWIN SCREW TIPLE SCREW PLASTIC EXTRUDER MACHINE

Application for Parrel Co-rotating Twin-Screw Plastic Extruder Machine

- Color Masterbatch;

- Filler Masterbatch

- Biodegradable Plastic granules and sheets: PLA, PBS with starch;

- Plastic sheets: PE, PP, PVC with starch powder or calcium carbonate powder;

- PET transparent sheets, etc.;

- Recycling film and bottle chips recovery granulation;

- Elastomer granules and Elastomer modification particles;

- Engineering plastic modification granulation

- Functional masterbatch: Anti-ageing, Anti-ultraviolet, ultraviolet light absorber, Anti-static and etc.;

- Reactive extrusion project: TPU, TPR, TPE, and other plastic and rubber materials

- Fire retardant masterbatch, flame resistance masterbatch;

- PET recycling granulation: PET waste film and PET bottle crushed or cracked chips;

- LGF (Long Glass Fibre) reinforced particles and Short Glass Fiber reinforced particles (needing side-feeder).

- Thermoplastic Elastomers

Parallel twin-screw extruder, twin-screw granulator, which models are used in what occasions? What is it used for?

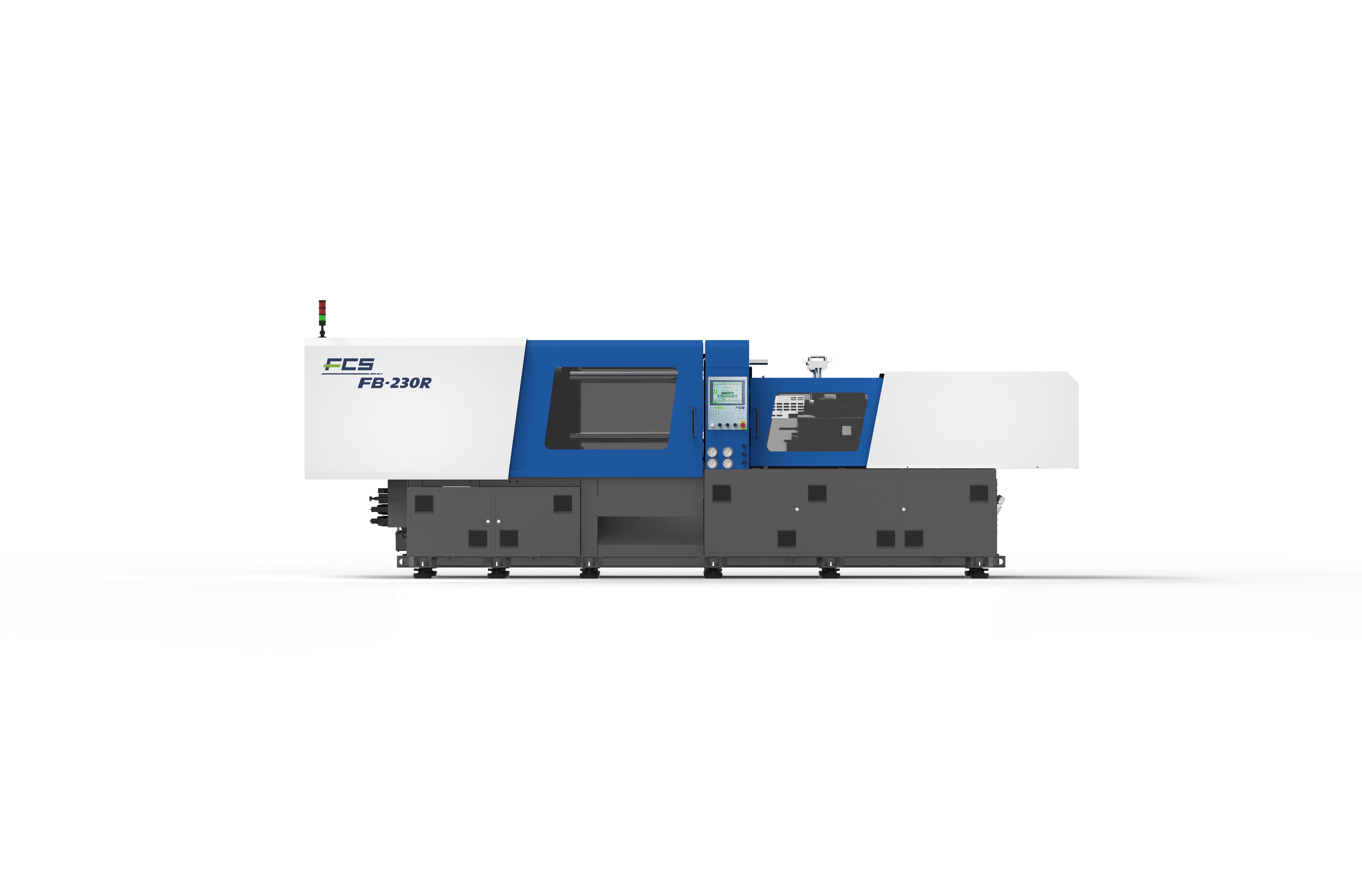

SHJ-20B/ 400RPM/500RPM/600RPM: laboratory model, mainly used to test whether the formula is feasible and the production process is reasonable; The explored data are only used as experiments and paper references, and all data cannot be directly amplified to use on large equipment;

SHJ-35B/35D/35G, 400-600RPM; Laboratory and small batch order production equipment, for the smallest type of production equipment, generally used for small batch multi-variety orders, but also can be used to test the reliability of the formula and the rationality of the production process; The experimental and operational data can be directly amplified to larger primary equipment and other large twin-screw granulation equipment. This kind of equipment is often the first choice for color manufacturers;

SHJ-50B/50D/52B/52D, 400-600RPM, this model is used for both particle quality and production capacity during granulation;

SHJ-65B/65D,400-600RPM, this model is used for modified products with a capacity of 150-200 kg per hour, which has taken into account the requirements of production capacity;

SHJ-75B/75D/75G, 400-600RPM, large capacity modification, granulation and sheet extrusion often used such equipment;

SHJ-95B/95D, 400-600RPM, large capacity modification, granulation and sheet extrusion require large capacity, will be used as the preferred equipment;

SHJ-110B or SHJ135B, 400RPM, large capacity requirements when the configuration, huge investment amount, have high requirements for power consumption and transformers, generally not recommended as a new user;

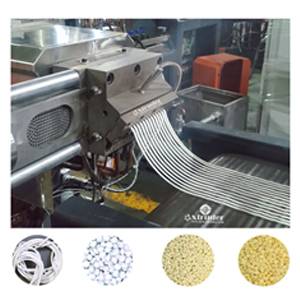

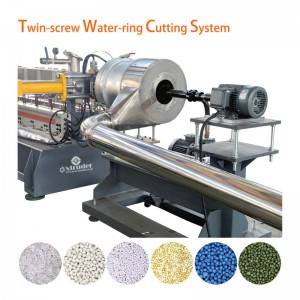

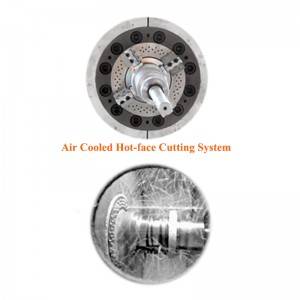

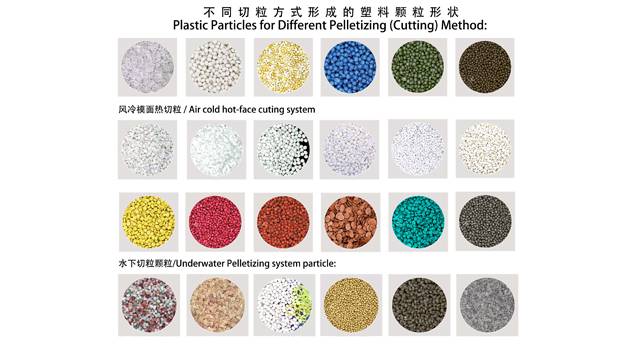

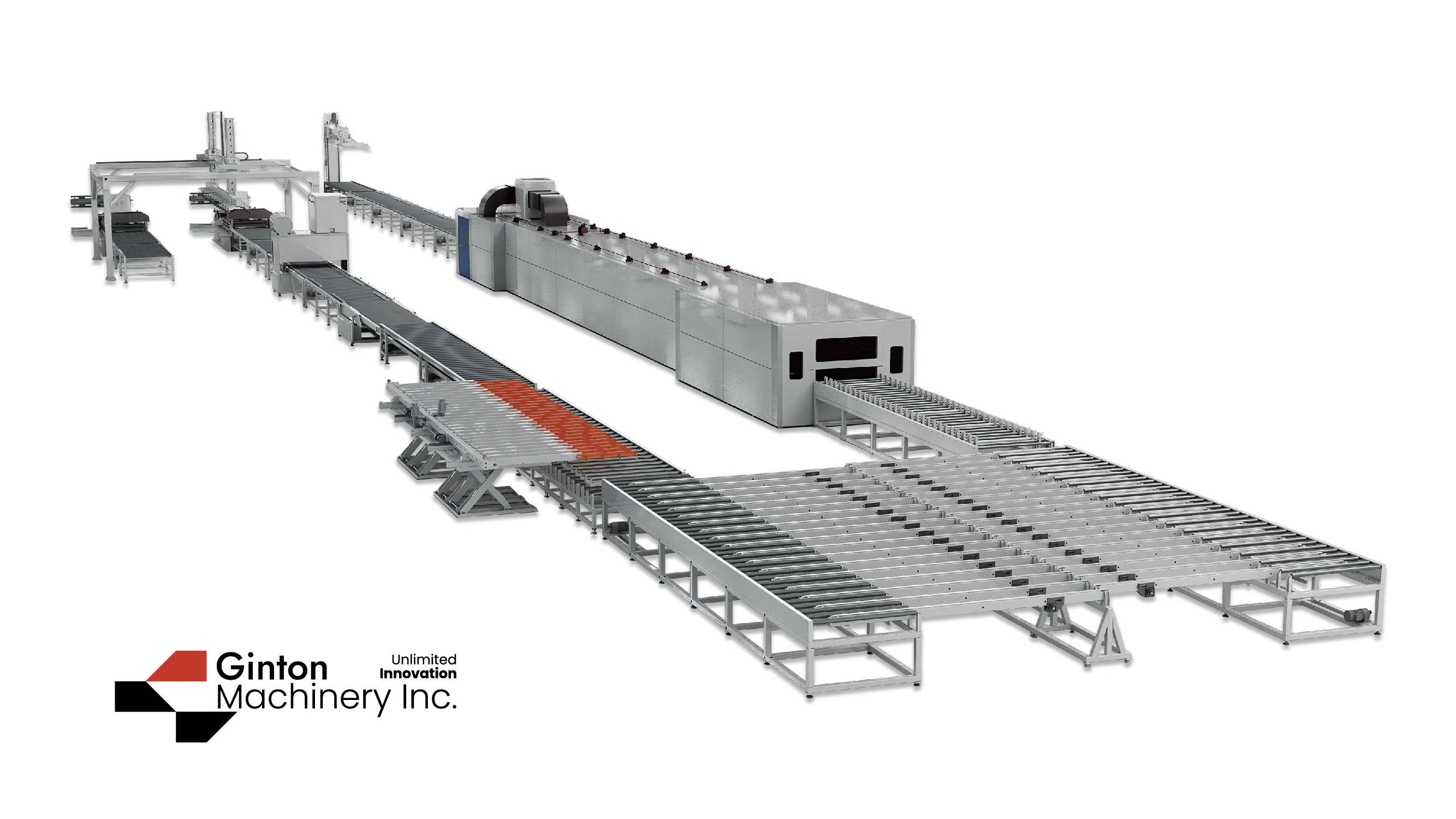

Different Method of Pelletizing system for Twin screw plastic extrusion machine:

| Strands bathing water cold pelletizing system | Strands Air cooling belt conveying system |

|  |

| Water-ring cold hot-face cutting system | Air–cooling hot-face cutting system |

|

|

| Underwater pelletizing system | PVC Cable extrusion group |

|

|

Different Method of Pelletizing system made Plastic Particles:

|  |

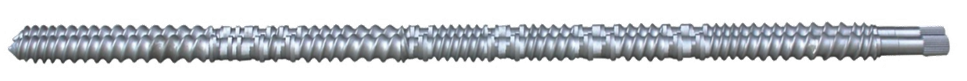

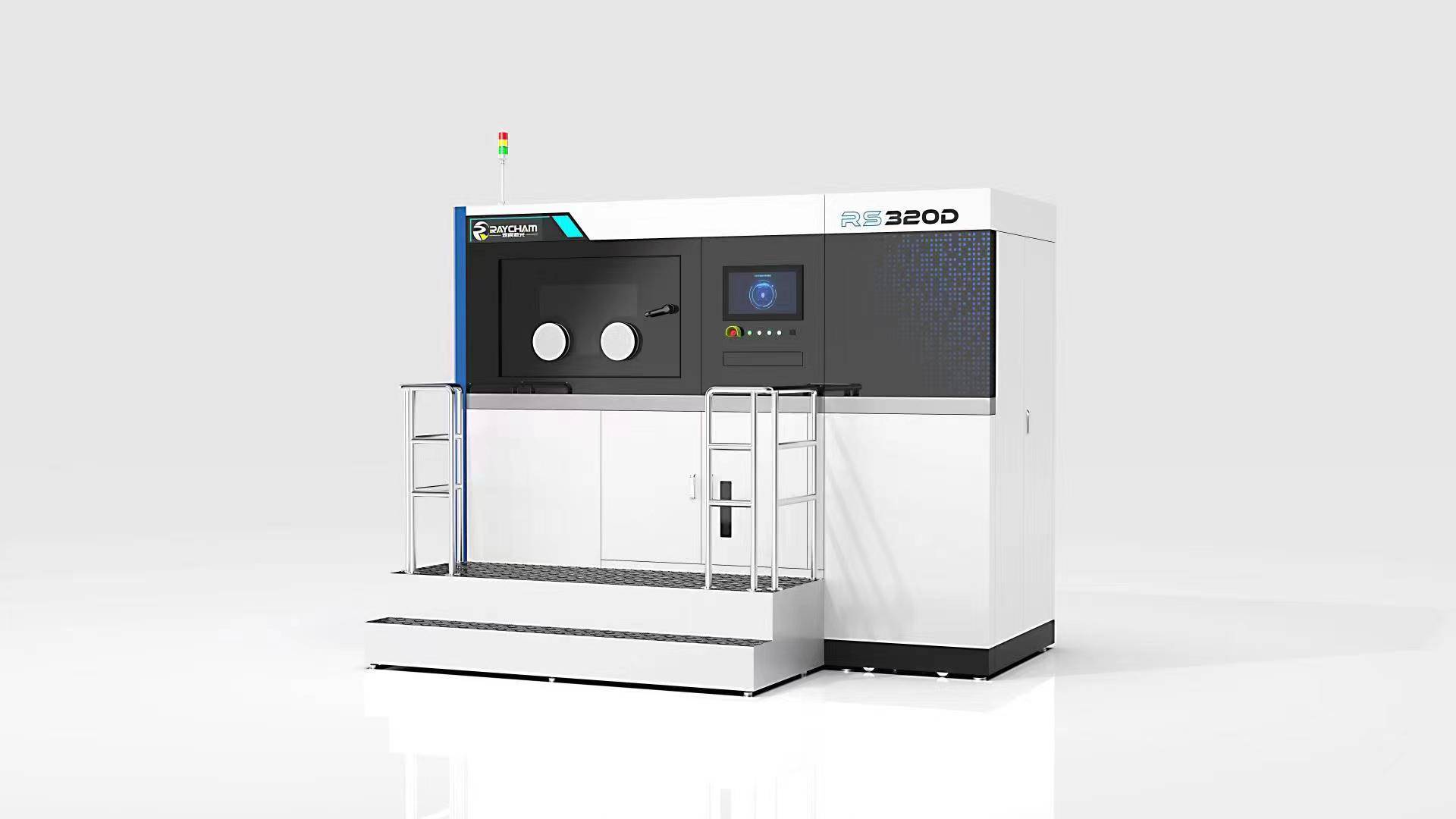

What is the L/D ratio about the twin screw plastic extrusion machine?

L/D is Length by screw diameter ratio, it means

Length-diameter ratio is the ratio of length to diameter.

For example, the diameter ratio of 50 machine is 40:1, which means the length =50x40=2000mm, it's also the length of shafts, but it isn't the length of the HOST's basement;

Normally, the L/D ratio of each barrel is 4:1;

|   |

|

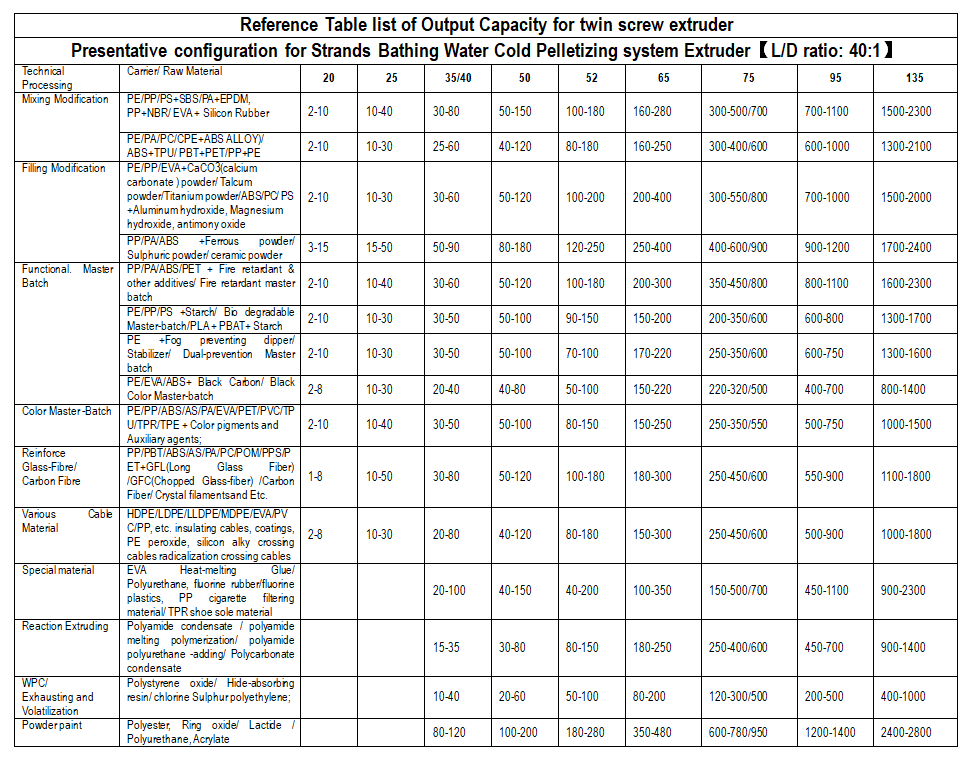

Table list for Applicable material for twin screw extruder | |

| Technical Processing | Carrier/ Raw Material |

| Mixing Modification | PE/PP/PS+SBS/PA+EPDM, PP+NBR/ EVA + Silicon Rubber |

| PE/PA/PC/CPE+ABS ALLOY/ABS+TPU/ PBT+PET/PP+PE | |

| Filling Modification | PE/PP/EVA+CaCO3(calcium carbonate ) powder/ Talcum powder/Titanium powder/ABS/PC/ PS +Aluminum hydroxide, Magnesium hydroxide, antimony oxide |

| PP/PA/ABS +Ferrous powder/ Sulphuric powder/ ceramic powder | |

| Functional. Master Batch | PP/PA/ABS/PET + Fire retardant & other additives/ Fire retardant master batch |

| PE/PP/PS +Starch/ Bio degradable Master-batch/PLA +PBAT+Starch | |

| PE +Fog preventing dipper/ Stabilizer/ Dual-prevention Master batch | |

| PE/EVA/ABS+ Black Carbon/ Black Color Master-batch | |

| Color Master Batch | PE/PP/ABS/AS/PA/EVA/PET/PVC/TPU/TPR/TPE + Color pigments and Auxiliary agents; |

| Reinforce GFL/Carbon Fiber | PP/PBT/ABS/AS/PA/PC/POM/PPS/PET+GFL(Long Glass Fiber) /GFC(Chopped Glass-fiber) / Carbon Fiber/ Crystal filamentsand Etc.; |

| Various Cable Material | HDPE/LDPE/LLDPE/MDPE/EVA/PVC/PP, etc. insulating cables, coatings PE peroxide, silicon alky crossing cables radicalization crossing cables |

| Special material | EVA Heat-melting Glue/ Polyurethane, fluorine rubber/fluorine plastics, PP cigarette filtering material/ TPR shoe sole material |

| Reaction Extruding | Polyamide condensate / polyamide melting polymerization/ polyamide polyurethane -adding/ Polycarbonate condensate |

| WPC/Exhausting& Volatilization | Polystyrene oxide/ Hide-absorbing resin/ chlorine Sulphur polyethylene; |

| Powder paint | Polyester, Ring oxide/ Lactide / Polyurethane, Acrylate |

Search

Search