Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

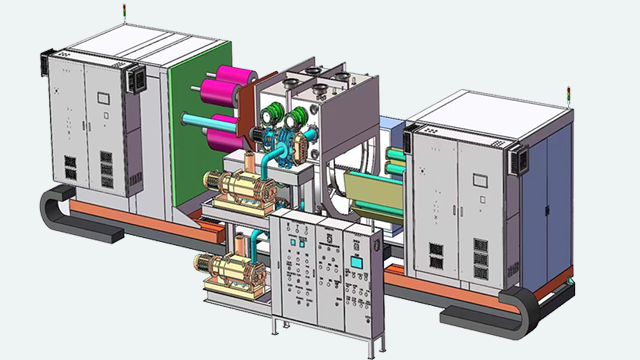

1. The "hard press soft" printing structure of "reverse first and then positive", each color group has an independent impression cylinder. Using a multicolor machine feeding method, some paper dust and paper dust are removed by the transfer roller before the paper enters the impression cylinder for printing, which reduces the number of downtime caused by the accumulation of paper dust. Since the reverse side is printed first and the reverse side is stamped twice, the print is reduced. If the reverse side of the product is scratched, the quality of the product is higher.

2. The operating space of the upper and lower groups is large, especially the operating space of the lower group reaches 1.32 meters high.(80% of customers do not dig trenches) The safe operation of the operators is effectively guaranteed.

3. There are no redundant paper transfer rollers between color groups, the number of handovers is less, and the quality of printed matter is higher.

4. Paper transfer shares a single bite, and the bite is as small as 6-8mm;

5. 2+2 adds an ink path clutch system.

serial number No. | name Description | RYS104G |

1 | Maximum paper size mm Maximum paper size mm | 720×1040 |

2 | Minimum paper size mm Minimum paper size mm | 393×546 |

3 | Maximum printing area mm Maximum printing area mm | 710×1040 |

4 | top speed Maximum operating speed r.p.h | 13000 |

5 | Paper thickness mm Paper Thickness mm | 0.03~0.3 |

6 | Printing plate size mm Printing plate size mm | 1050×800×0.28 |

7 | backing paper mm Backing paper mm | 1045×760×0.65 |

8 | Blanket size mm Blanket Size mm | 1050×930×1.95 |

9 | Height of paper carriage mm Feeder Unit height mm | 1500 |

10 | Delivery table height mm Delivery Unit height mm | 1100 |

11 | Machine size mm Machine size mm | 6100×3800×2850 |

12 | Total machine power kw Total machine power kw | 22.5 |

13 | Main motor power kw Main motor power kw | 15 |

14 | Machine weight t Machine weight t | 16.8 |

15 | Specific borrowing amount (axial direction) mm Plate adjustment (axial direction) mm | -2.5~+2.5 |

16 | circumferential mm Circumferential mm | -0.8 ~+0.8 |

Search

Search