1 / 1

AK Optics Wafer Surface Profile Inspection and Sorting System

Price:

price negotiable

Brand Name:

AK Optics Country Region:

ChinaModel No:

SPI300

Post Requirements

Post Requirements

AK Optics

Country: China

Main Products:

View more

Price:

price negotiable

Brand Name:

AK Optics Country Region:

ChinaModel No:

SPI300

Post Requirements

Post Requirements

AK Optics

China

Main Products:

Product information

The SPI300 geometry measurement equipment

Wafer Size Compatibility**: 4", 6", 8" compatible

Standard configuration includes 16 cassettes or 14 cassettes (optional/WA), with all cassettes freely configurable for loading and unloading, allowing for flexible sorting.

Inspections category: Thickness, TTV, bow, warp, TIR (Total Indicated Reading), sori, sag, LTV (requires full map inspection).

SPI300 can output CSV data reports and allows for customized saving of line scan and area scan 2D/3D surface profile PDF reports.

Measurement Specifications

Wafer Thickness Range: 400µm - 2000µm

Probe Resolution: 0.028µm

Measurement Accuracy: ±0.2µm

Repeatability: 3σ ≤ 1.0µm

Accuracy: THK/Bow/Warp linearity ≥ 95% , TTV/TIR linearity ≥ 90%

Software Features

Function Blocks: Wafer handling control, status indication, safety interlock, data acquisition, wafer sorting, measurement result data viewing and storage, recipe editing and management, equipment status logging.

User Permissions: Engineer, Operator

Grading Function: The grading function allows user to define product grades A/B/C/NG based on their requirements.

Parameter Definition: User can independently set inspection parameters and control standards.

All products in the store

F2000 Particle counter

H2000 integrated circuit graphic wafer front defects

Wafer Surface Profile Inspection and Sorting System

SiC Wafer Defect Inspection System

You May Like

FalconWave®-S High Resolution Product

DENBA HEALTH

![[Used] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

[Used] laser

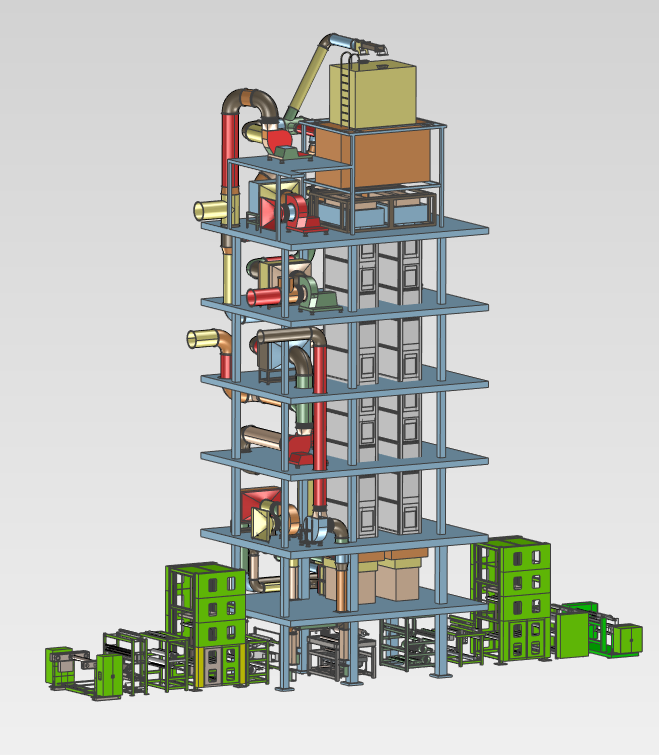

High pressure atomization and spraying system

6/8 inch resistor long crystal furnace

Optical anti-reflection coating continuous line

Electronic manufacturing of X-Ray inspection equipment

Titanium products、Copper alloy products

IR Vertical Impregnation Machine

Molecular beam epitaxial system MBE

Search

Search