Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

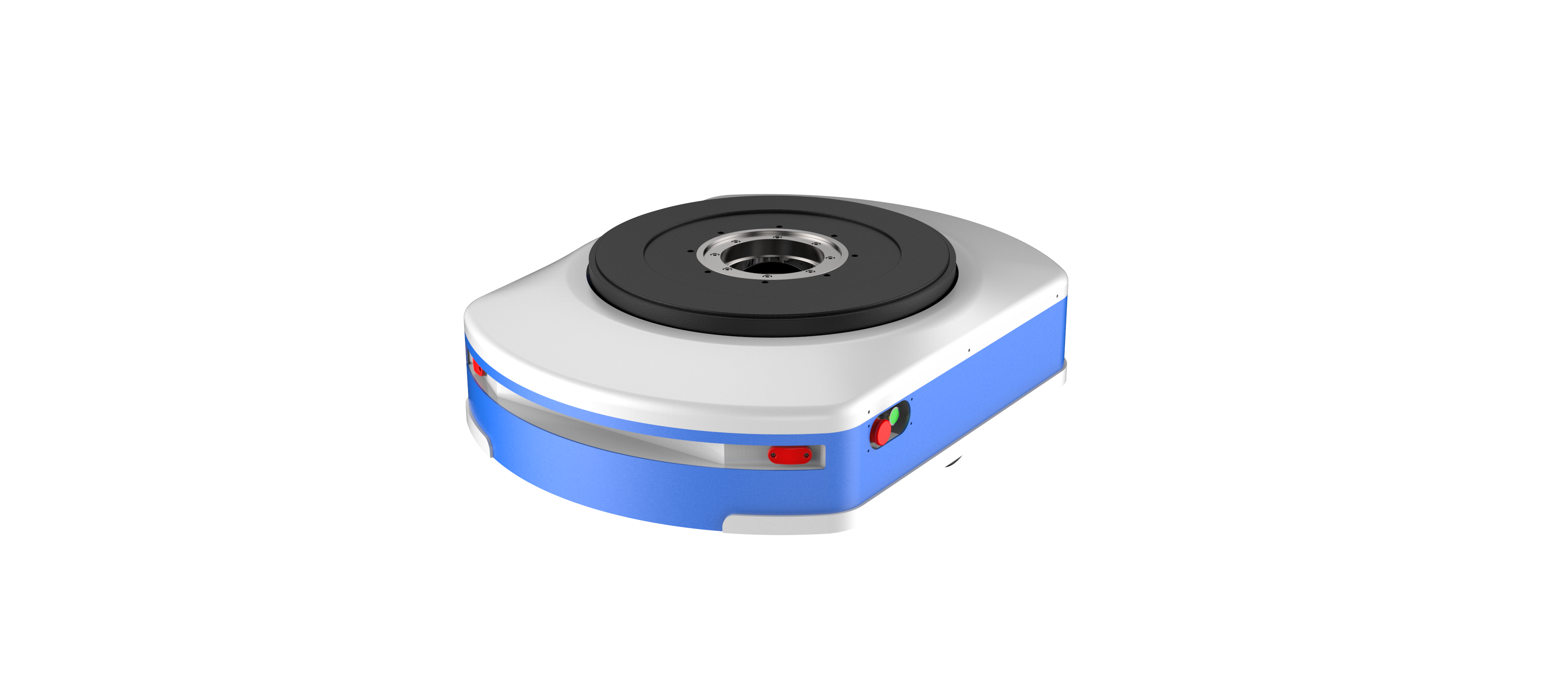

1、Introduction

The ZY-200 intelligent sample storage cabinet is specialized in the storage of various bulk samples in the laboratory, and can achieve closed and centralized control of samples. The equipment is controlled by PLC and operated through human-machine dialogue touch screen, which is simple and fast. It can run independently or be integrated into automation systems.

This machine requires external compressed air.

2、Main features

2.1 Built in 200 workstations, each with 1 1200mL stainless steel cup.

2.2 The equipment is controlled by PLC and parameters can be defined on a touch screen. A detailed human-machine interface with functions including: operating status, process history, historical data, alarms, expiration reminders,etc.

2.3 The equipment adopts a fully enclosed design, achieving centralized control of the samples in a closed manner, and storing/retrieving them according to their ID with permission. Graded permission control to meet management, operation, maintenance, and query requirements.

2.4 Two input and output ports, one for manual use and one for docking with automation systems (optional)

Search

Search