Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

1、Introduction

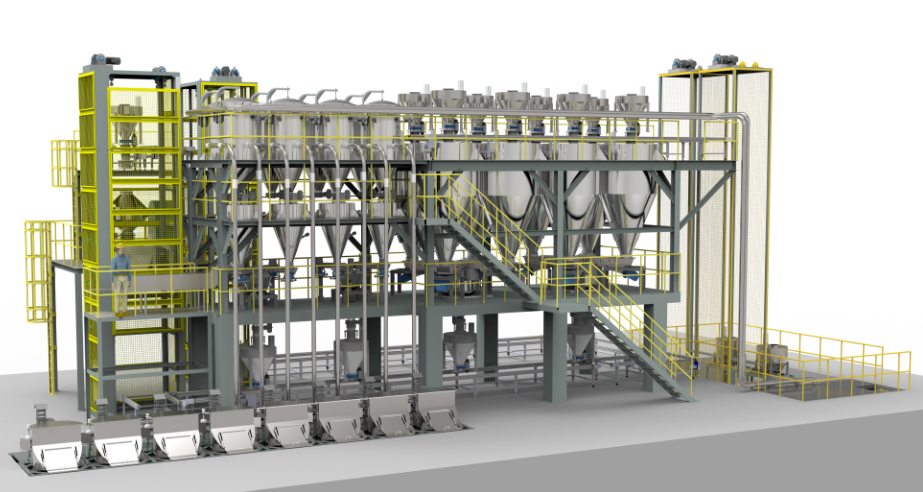

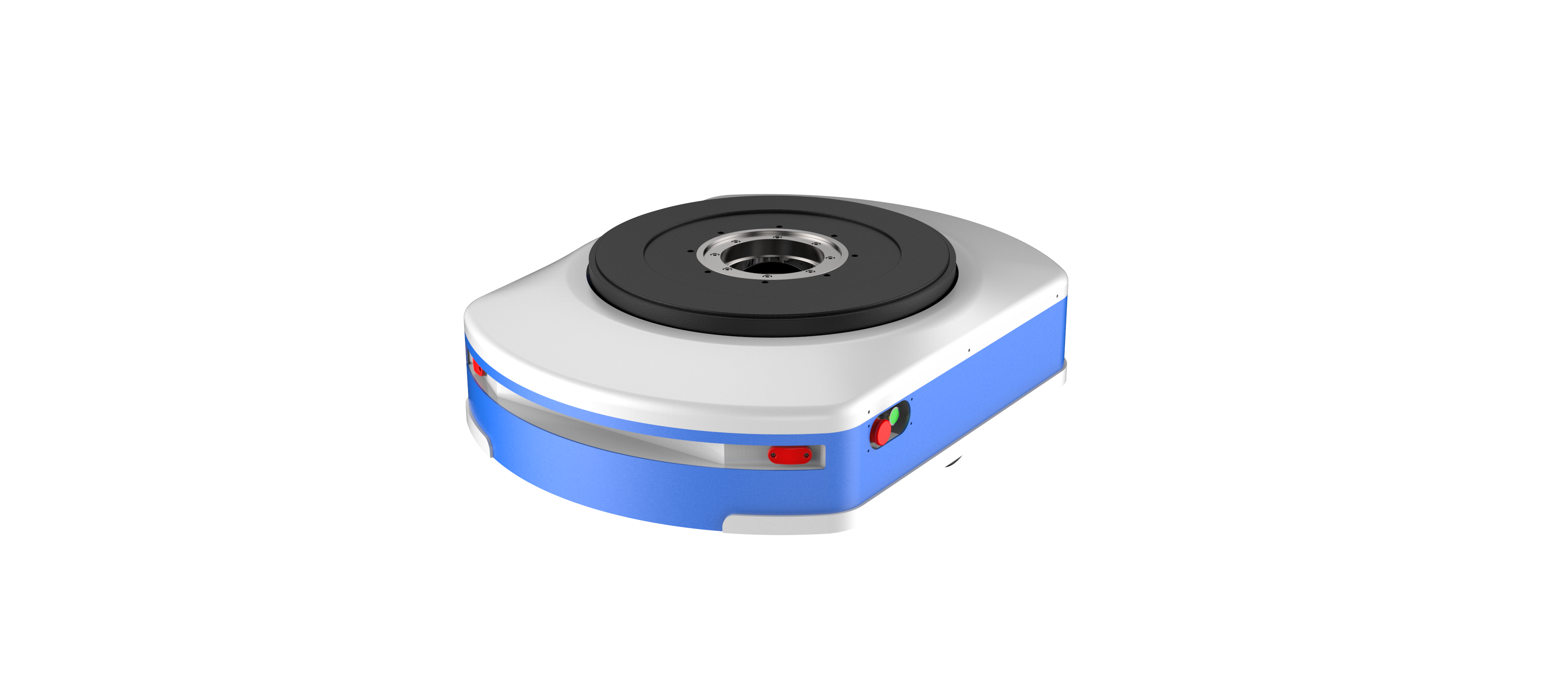

The ZRS-AT pneumatic transceiver station is an automatic transceiver station with the function of automatic opening of sample boxes. Used for receiving sample box containers containing powder and block samples in the laboratory. The sample box is directly taken out by manual or robot, unloaded, placed in the container, and automatically closed and sent. Reserved automation interface.

This machine requires external compressed air.

2、Main features

2.1 Compressed air positive pressure delivery sample box.

2.2 The equipment is controlled by PLC and parameters can be defined on a touch screen.

2.3 The sample box has arrived and the pneumatic lid is opened inside the transceiver station. Before sending the empty sample box, automatically close the lid with pneumatic pressure.

2.4 Equipped with deceleration and pressure relief devices, combined withprogram control, to achieve soft landing when the sample box arrives.

2.5Double sided operation window, front for manual sampling box and touch screen operation, back reserved window for robot sampling box in automation system

2.6 Safety chain design ensures the safety of sampling box operations.Automatic fault monitoring, alarm, and information guidance for disposal.

Search

Search