Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

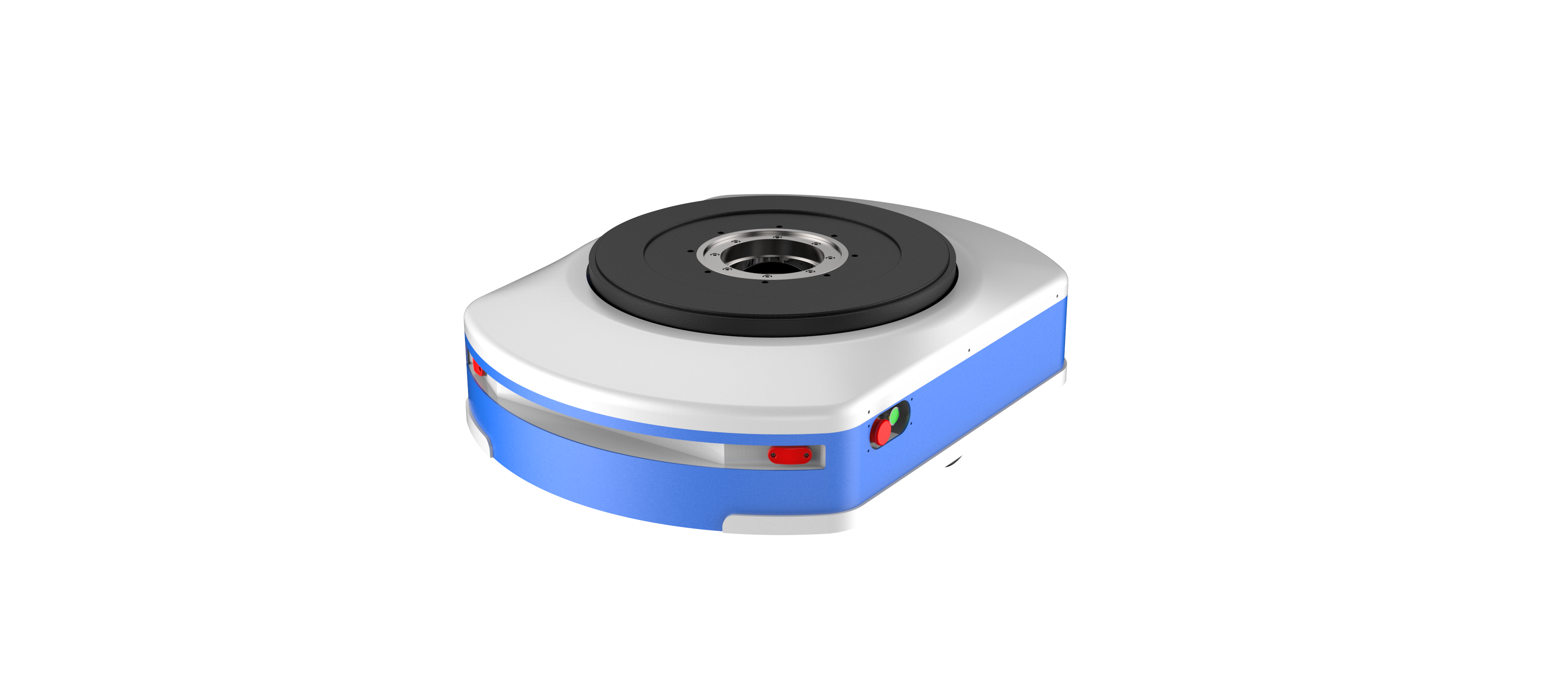

1、Introduction

The MS-Z fully automatic grinder is a fully automatic equipment that integrates functions such as automatic feeding, grinding, discharging, cleaning and dust removal. It is mainly used to make powder samples of minerals (ferroalloys, acid salts, cement,ceramic raw materials, ores, sintered ore, and slag) into powder samples that can be used for chemical analysis, XRF or XRD pre-treatment.This machine requires external compressed air and dust removal pipelines.

2、 Main features

2.1 Fully sealed sound insulation treatment, with reserved dust removal interface and compressed air interface.

2.2 The flange plate and vibration frame of the electric motor are fixed with bolts, and the power of the vibration machinery is generated by the eccentric block on the rotating electric motor shaft.

2.3 The equipment is controlled by PLC and operated on a touch screen. According to the characteristics of different material varieties, grinding parameters can be defined. Multiple sets of parameters can be defined.

2.4 A sealed tungsten carbide material grinding device with automatic grinding,discharge, compressed air blowing and cleaning, and synchronous automatic dust removal.

2.5 The equipment can run independently and also has reserved interfaces for automation integration

Search

Search