1 / 1

Nanjing HEAO Cup shaped grinding wheel grinding machine

Price:

price negotiable

Brand Name:

Nanjing HEAOCountry Region:

ChinaModel No:

HGW-200

Post Requirements

Post Requirements

Nanjing HEAO

Country: China

Main Products: Raw material sampling testing and pneumatic sampling analysis, fast automatic sampling of molten iron, molten steel, slag before steelmaking furnace, sampling before physical performance testing, environmental protection water quality automation series. The company's product types are divided into large-scale integrated intelligent automation system, small and medium-sized linear automation system and single system sample equipment; The intelligent automation system includes: the automatic system of quick sorting in front of the furnace, the intelligent automation of raw material acquisition, production, storage, delivery and sorting, the automatic system of material sample preparation and the intelligent composite raw material sample preparation system. Small and medium-sized linear automation systems include: ferroalloy sample preparation system, ore auxiliary materials sample preparation system, coke two-stage sample preparation system, etc. Stand-alone products include: rapid milling machine, automatic cutting machine, grinding and pressing machine, intelligent composite sample preparation equipment, automatic grinding wheel grinding machine, etc.

View more

Price:

price negotiable

Brand Name:

Nanjing HEAOCountry Region:

ChinaModel No:

HGW-200

Post Requirements

Post Requirements

Nanjing HEAO

China

Main Products:

Raw material sampling testing and pneumatic sampling analysis, fast automatic sampling of molten iron, molten steel, slag before steelmaking furnace, sampling before physical performance testing, environmental protection water quality automation series. The company's product types are divided into large-scale integrated intelligent automation system, small and medium-sized linear automation system and single system sample equipment; The intelligent automation system includes: the automatic system of quick sorting in front of the furnace, the intelligent automation of raw material acquisition, production, storage, delivery and sorting, the automatic system of material sample preparation and the intelligent composite raw material sample preparation system. Small and medium-sized linear automation systems include: ferroalloy sample preparation system, ore auxiliary materials sample preparation system, coke two-stage sample preparation system, etc. Stand-alone products include: rapid milling machine, automatic cutting machine, grinding and pressing machine, intelligent composite sample preparation equipment, automatic grinding wheel grinding machine, etc.

Product information

1、Introduction

The HGW-200 cup type grinding wheel prototype is controlled by PLC and is mainly used for automatic grinding of metal samples, removing the oxide layer on their surface, and obtaining flat samples required by OES or XRF. Suitable for the preparation of various irregular shapes (cake, racket, circular truncated cone etc.) in the laboratory

2、 Main features

2.1 Closed structure ensures the safety of the grinding wheel grinding process.

2.2 Small size, compact structure, hydraulic pressure driving, low noise and vibration, built-in dust suction, and simple maintenance.

2.3 The equipment is easy to operate, and the grinding process is fully automatic, which can be completed with just one click on screen.

All products in the store

Rapid sample milling machine

Tensile specimen edging machine

Laboratory tablet press machine

Non-ferrous metal milling machine

Rapid sample milling machine

Pneumatic transceiver station

You May Like

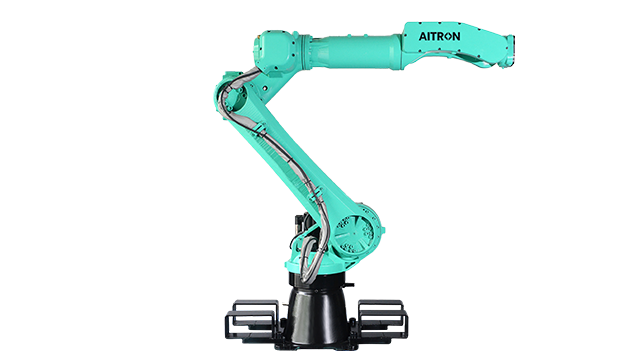

Industrial robot

High pressure atomization and spraying system

Optical anti-reflection coating continuous line

Fast forging hydraulic press

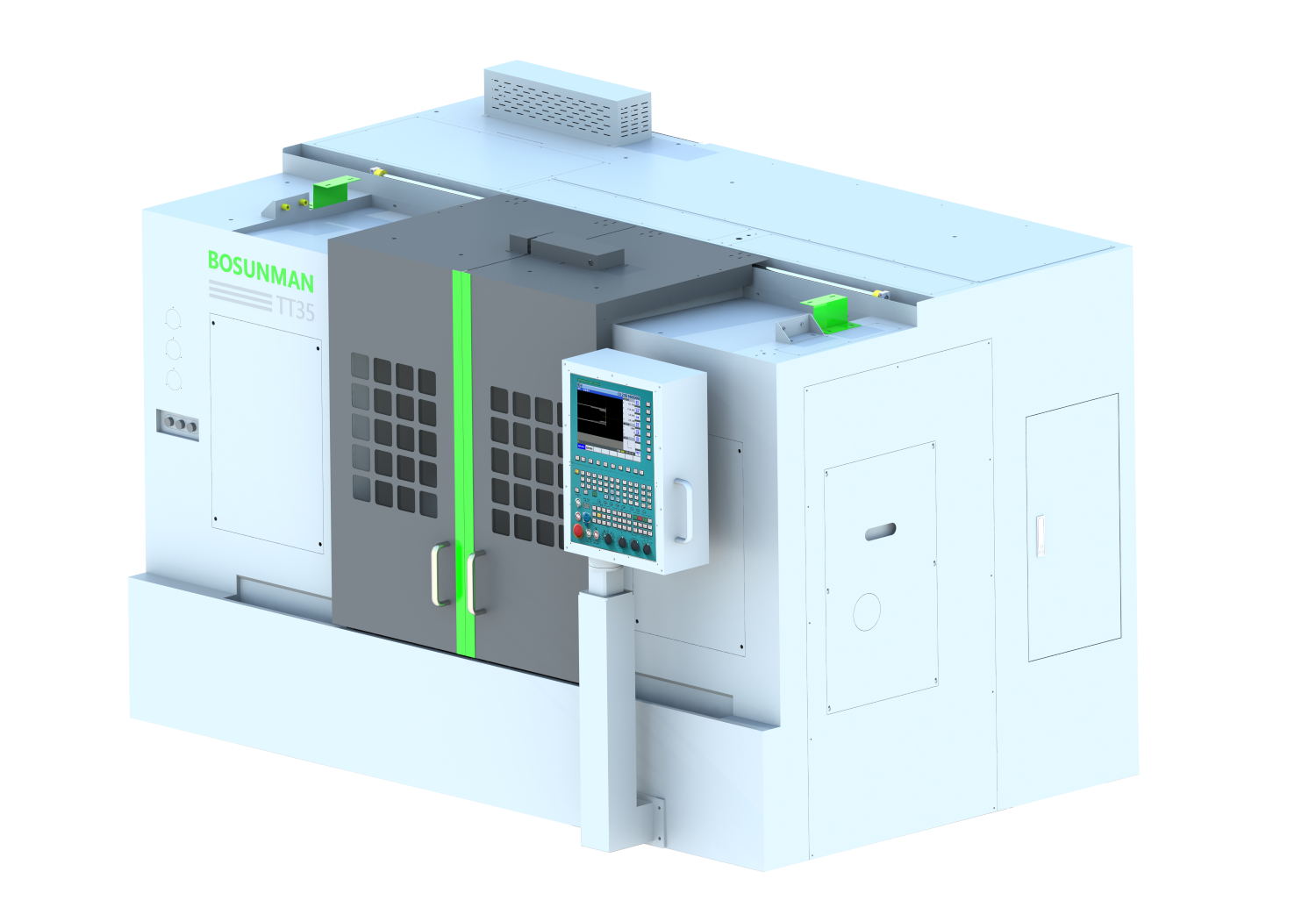

Double spindle double tool tower turning center

Hermos Precision CNC internal grinder

Industrial robot

Hwavy turret lathe

5 Axis 3D Fiber Laser Cutting Machine

Online density control system

Search

Search