Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

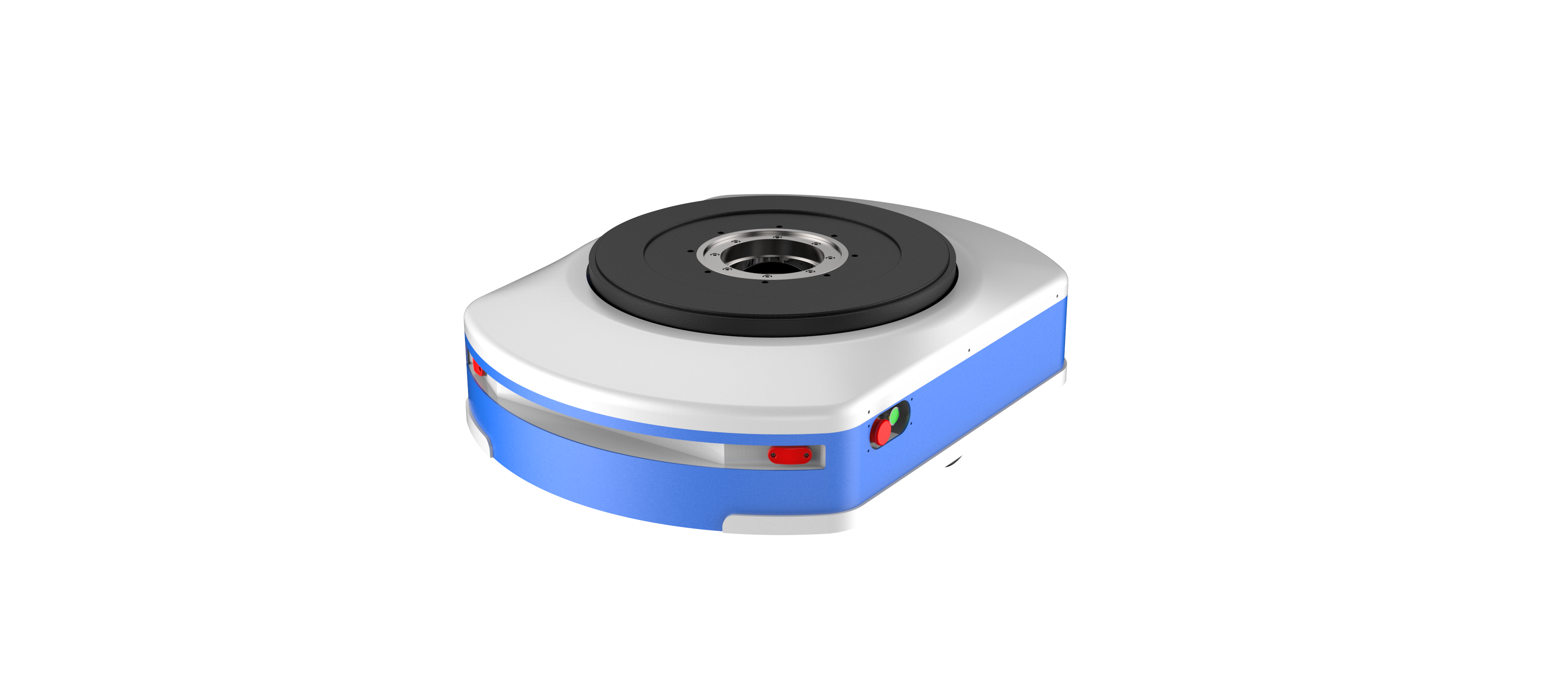

1、Introduction

The QG-60Z fully automatic metal cutting machine is one of the equipment specialized in analyzing and pre-treatment of metal samples in metallurgical laboratories. The device automatically segments and cuts the samples according to requirements to obtain metal sheets without oxidation and overheating, which are used for further preparation of instrument analysis samples such as oxygen, nitrogen, carbon, and sulfur. Save time and improve efficiency

2、Main features

2.1 Closed structure, safety door protection, automatic sample delivery, ensuring the safety of the cutting process.

2.2 Metal alloy cutting blades have a long service life and improve the quality of the cutting surface, ensuring that the sample is free from overheating and surface oxidation.

2.3 PLC automatic control, adjustable feed rate and cutting length, touch screen operation, simple and convenient.

2.4 Compact structure, low noise and vibration, built-in dust collection, and simple maintenance.

2.5 Hydraulic clamping device, stable and reliable.

Search

Search