Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

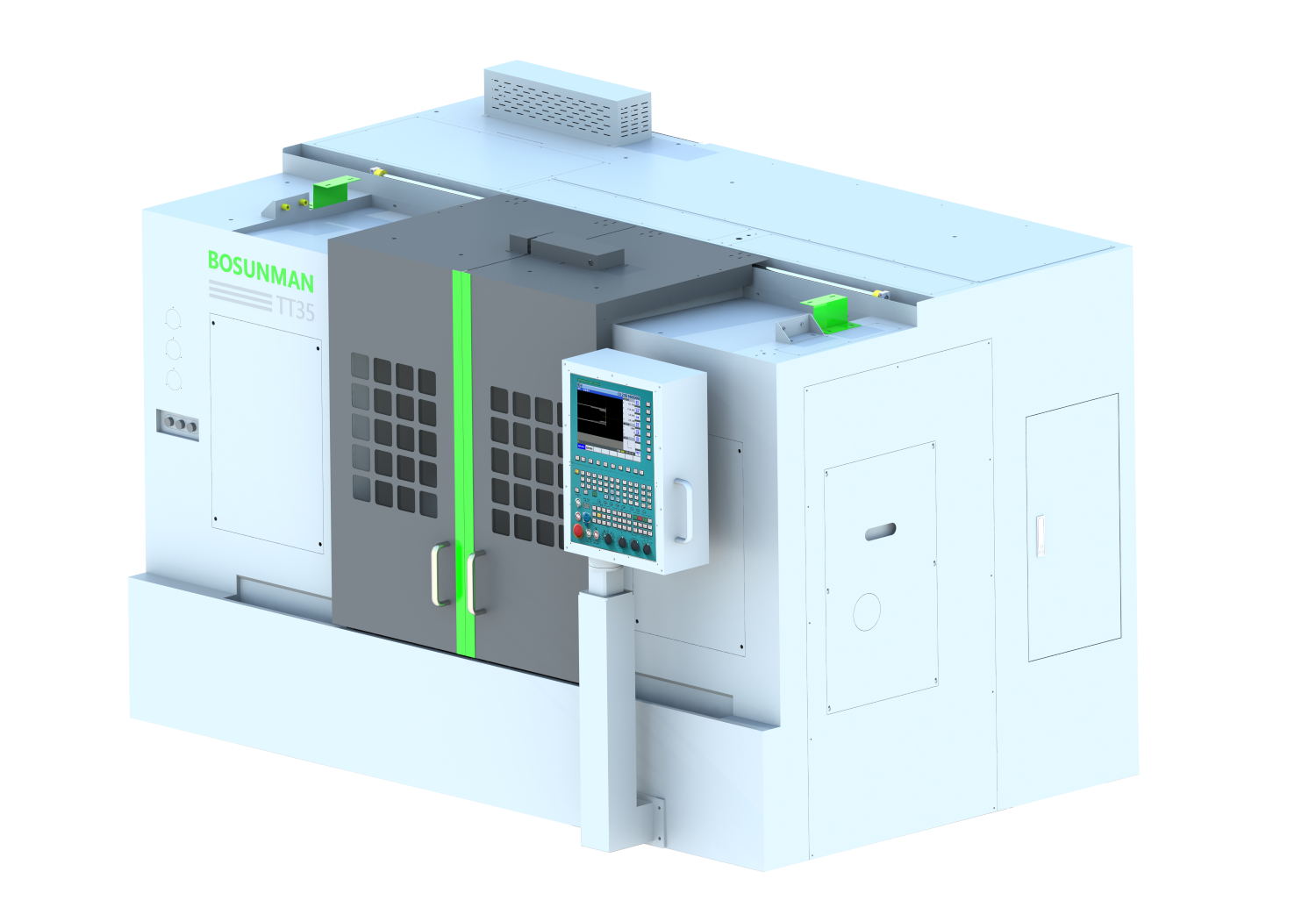

All use European made electric spindles, and key precision components such as C3 level high-precision lead screws and 45mm P-type roller linear guides are made by top European manufacturers. Using SIEMENS/HEIDENHAIN motors. 840Dsl CNC system (15.6 "/19") pre reading program 1000 segments. The X/Y/Z axis motor adopts high inertia, standard 3-axis or 5-axis machining process package, including 3D simulation/optimized surface/rich 3D dynamic process cycle/spline interpolation/ShopMill step programming/surplus material recognition processing/synchronous recording/6G memory/5-axis linkage, etc. The standard configuration includes a 20 bar spindle, all of which use high-performance electric spindles with a maximum spindle speed of 24000 rpm. Adopting SIEMENS/HEIDENHAIN high-speed feed servo motor, it has high speed, efficiency, rigidity and precision performance, effectively reducing non machining time. CNC uses HRV3+current loop control to achieve nano interpolation of the motor, and the star delta winding instantaneous switching function selects the winding form separately, which can provide higher torque in a series of ranges. Through the fast switching function, the machine's acceleration/deceleration rate is maximized, thereby improving machining capacity and shortening machining time. Equipped with personalized features such as CF card online editing, intelligent reverse clearance compensation, and spindle intelligent load.

Search

Search