Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Product characteristics and technical advantages

1. The hammer plate adopts an overall hot charging process, so that the rotor runs more smoothly;

2. The rotor structure is strengthened and is not easy to crack;

3. The spindle is forged with 40Cr or 42CrMo + tempered. Compared with traditional spindles, it has better impact resistance and stronger reliability.

4. The carrier bars and mandrel are treated with 40Cr quenching and tempering, and the spacer sleeves are cut with wear-resistant plates, which significantly improves the service life of wearing parts.

Shanyuan Brand PC Series-Hammer Crusher. Compared with traditional hammer crushers, more optimized designs have been made and have a larger crushing ratio (generally 10-25, and some can reach 50); the optimized design makes the whole machine more compact and easy to operate and maintain. It is widely used in crushing medium hardness materials in cement plants, large-scale sand and gravel aggregate production line projects, mineral processing equipment, ceramic raw materials and other fields.

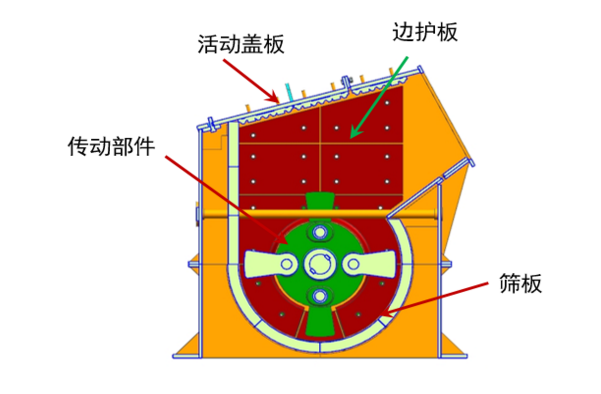

working principle

PC Series-Hammer Crusher is mainly composed of rotor, shell, sieve plate and driving part. It mainly relies on the hammer head of the crusher to carry out a strong blow to the ore in the upper chamber. The ore is crushed by the impact of the ore on the guard plate and sieve plate and the collision between the ore. After the raw ore is fed into the feed inlet of the crusher through the feeding equipment, it falls into the crushing chamber between the high-speed rotating rotor driven by the narrow V-belt and the sieve plate, and is initially crushed by the hammer head. The initially crushed material is further crushed again between the rotor and the sieve plate during downward movement, and then the lower crushing chamber formed by the sieve plate and the rotor is finally crushed until the particle size is smaller than the screen hole size and discharged from the lower part of the machine chamber.

Search

Search