Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Steel Rolling Definition, Process, Equipment, Technology, and Applications

Definition: Steel rolling is a metal forming process that involves applying pressure to metal billets through rotating rolls, causing plastic deformation and ultimately transforming them into steel products of the desired shape, size, and properties.

Principle: Similar to pressing dough into noodles, steel billets undergo multiple compressions and advancements through the rolling mill, resulting in various specifications of steel products.

Steel Rolling Process and Equipment

Process: The steel rolling process encompasses heating, rolling, cooling, and finishing stages. Heating softens the steel billets, facilitating the rolling process; rolling applies pressure via rolls, causing plastic deformation; cooling is essential for achieving the desired microstructure and properties of the rolled steel; and finishing involves further processing and treatment to meet customer specifications.

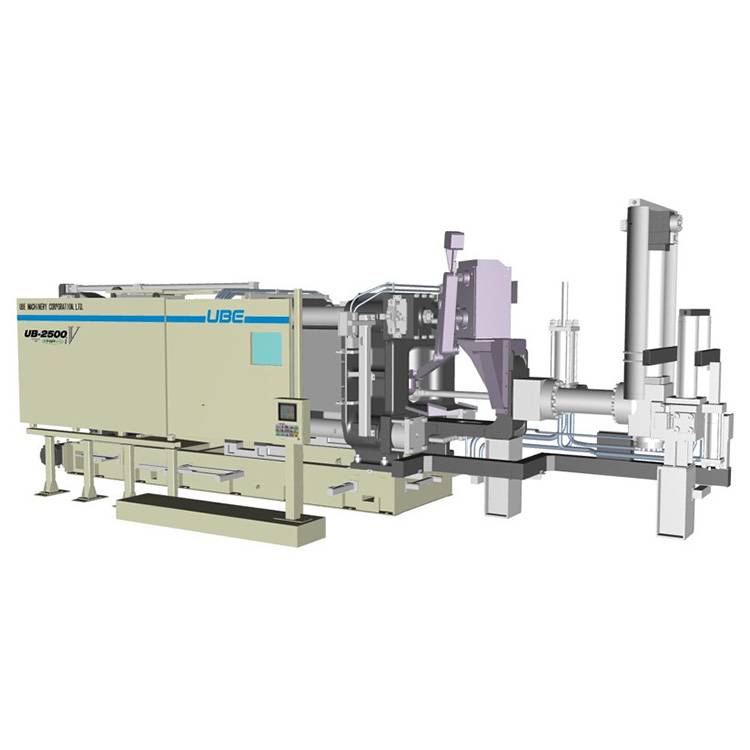

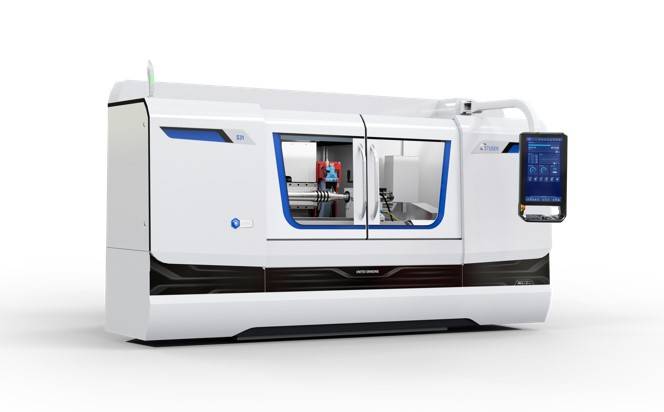

Equipment: The primary equipment in steel rolling includes rolling mills, heating furnaces, cooling devices, and finishing equipment. The rolling mill is the core of the steel rolling process. Based on purpose and specifications, rolling mills can be classified as blooming mills, slabbing mills, section steel rolling mills, plate and strip rolling mills, and steel pipe rolling mills.

Steel Rolling Technology and Techniques

Hot Rolling and Cold Rolling: Hot rolling takes place at high temperatures, allowing for the production of large-sized, high-performance steel products. Cold rolling, conducted at room temperature, produces steel with high precision and excellent surface quality.

Controlled Rolling: By manipulating parameters such as temperature, deformation amount, and rolling speed during the rolling process, steel with superior microstructure and properties can be obtained.

Special Rolling Techniques: These include section steel rolling, seamless steel pipe rolling, plate and strip rolling, etc. These specialized techniques cater to specific needs in various industries and customer requirements.

Applications of Steel Rolling

Machinery Manufacturing: Steel rolling produces steel materials of various shapes, sizes, and quantities, suitable for components in various machinery manufacturing industries, such as power machinery, textile machinery, agricultural machinery, and mining machinery.

Construction Industry: Steel rolling supplies materials like angle steel, I-beams, and flat plates essential for structural support and connections in buildings.

Aerospace and Defense Industries: Steel rolling produces high-strength, high-hardness, and corrosion-resistant steel suitable for various materials in high-tech fields like aerospace and defense.

Petrochemical Industry: Steel rolling provides high-quality steel for equipment such as oil and gas pipelines, tanks, and pressure vessels, characterized by corrosion resistance, high toughness, and high strength.

Automobile Manufacturing Industry: Steel rolling produces various steel materials for automobile manufacturing, such as wheels, frames, and bodies, featuring high strength, wear resistance, and toughness.

Search

Search