Post Requirements

Post Requirements

Post Requirements

Post Requirements

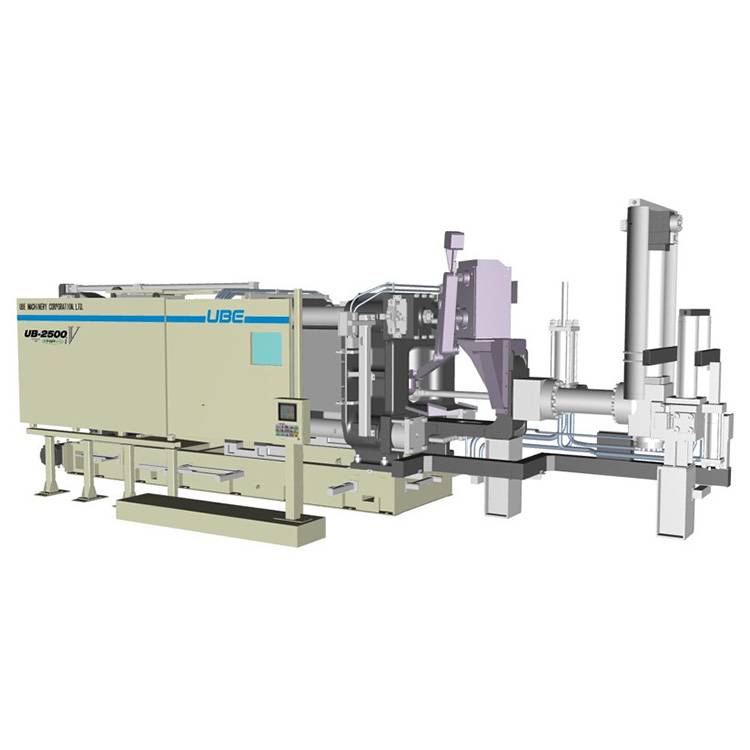

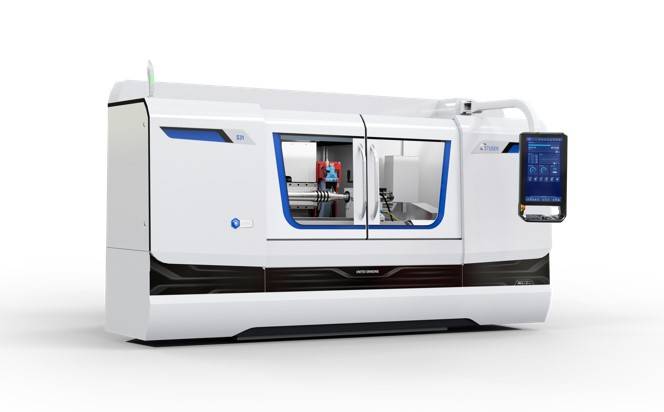

Product information

Characteristics of Waste Heat Resources

Waste heat resources are characterized by high temperature and high energy content, stability, diversity, and widespread distribution. These characteristics make waste heat resources possess broad application prospects in industrial production. For instance, in industries such as steel, chemicals, and glass manufacturing, heating furnaces, kilns, and other equipment generate substantial waste heat during operation. Effective utilization of this waste heat can significantly reduce energy consumption and production costs.

Types of Waste Heat Comprehensive Utilization Technologies

Waste heat comprehensive utilization technologies encompass various types, with the following being some of the primary ones:

Cogeneration Technology: Utilizes cogeneration equipment to convert waste heat into electrical energy and thermal energy. This technology enables dual utilization of energy, thereby improving energy utilization efficiency.

Hot Water Heating Systems: Employs waste heat for heating systems, transporting it through pipelines to areas requiring heating. This technology not only promotes energy conservation and emission reduction but also meets urban heating demands.

Organic Rankine Cycle (ORC) Power Generation Technology: A technology that utilizes heat to produce electrical energy. Through ORC devices, waste heat is converted into electrical energy, achieving energy recycling.

Low-Temperature Absorption Heating/Cooling Units: Utilizes industrial waste heat as a heat source or cold source to fulfill heating or cooling functions. This technology boasts low power consumption, low noise, smooth operation, and environmental friendliness, without damaging the atmospheric ozone layer.

Vacuum Phase Change Direct Heating Units: Leverages heat from medium-to-high-temperature industrial wastewater. Through a flash evaporation process in a negative pressure environment, clean steam is produced and exchanged in a condenser to obtain clean water. This technology can be applied to recover waste heat from industrial wastewater and process cooling water exceeding 50°C generated during production processes in industries such as chemicals, metallurgy, and textiles.

Industrial Steam Waste Heat and Pressure Comprehensive Utilization Technology: Conducts water-vapor separation on high-temperature condensate water, extracts the waste steam, pressurizes it, and injects it back into the steam supply pipeline. This technology saves steam consumption and enhances energy utilization efficiency.

Search

Search