Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Advantage

1.Integrated the ability of Calendering and Slitting of Lithium Battery Electrode

2.Gap adjustment by Hydraulic Servo-motors, available to control pressure andgap adjustment by close-loop system

3.Laser thickness measurement system including the ability of online electrodethickness control by close-loop

4.Main Rollers fast change device

5.Including moveable scraper with nonwoven roller cleaning device

6.Installed with special electrode slitting device, have the features of high wearresistance and high precision, allow fast changing

7.Close-loop tensile control system

Line Description

Electrode Calendering & Slitting Integrated Line is to calendaring the coated positive/ negative electrodes through a continuous hydraulic press roller device, to improvethe thickness uniformity based the customer requirement, and then slit it into severalpcs of electrodes of the requested width, and winding properly in the end.

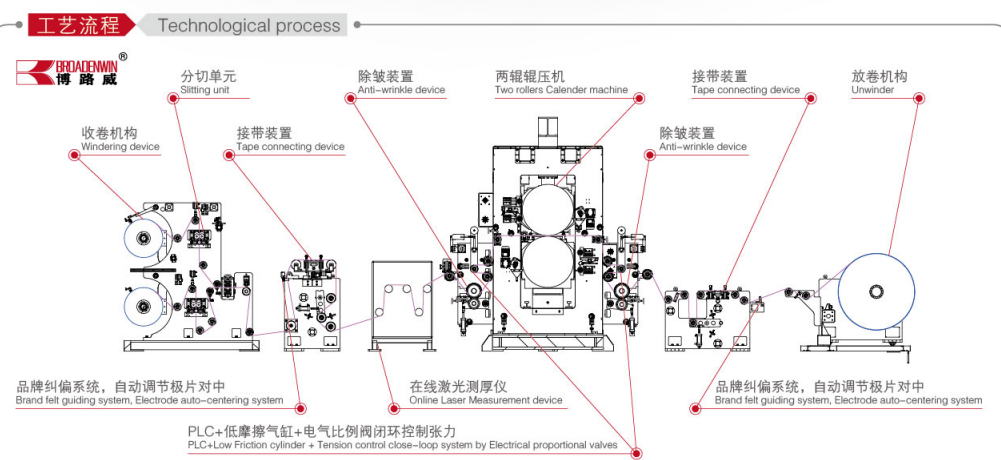

Process route

The production line is mainly composed of unwinder system, wrinkle removal mechanism,roller press, online thickness measurement system, winder system, guiding system and slitting unit, to complete the calendering and slitting process of the electrode, improve the compaction density and improve the thickness uniformity.

Search

Search