Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

XCooling Energy-Saving Heat Pipe Backplane Air Conditioner

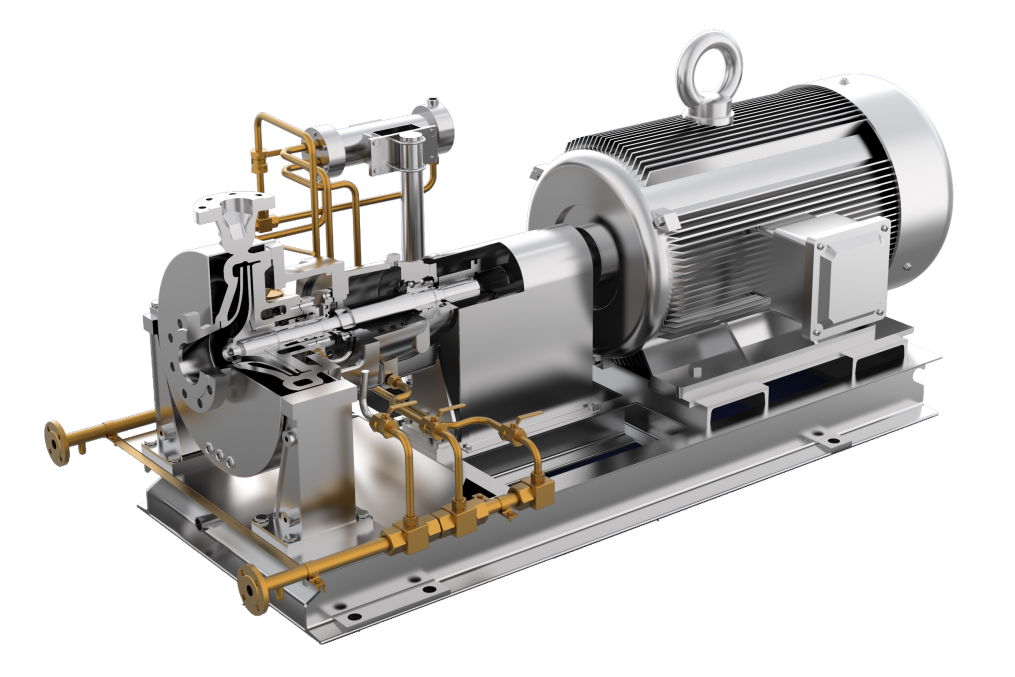

Canatal xCooling energy-efficient heat pipe backplane air conditioner is a highly efficient heat dissipation product that is installed close to the heat source and integrated with the server rack. The unit uses heat pipe technology, combined with a cooling capacity distribution unit and a cooling source device, to cool the hot air discharged by the server and discharge it into the indoor environment, forming an indoor cold pool. The unit is installed on the rear door of the server rack and uses indirect heat exchange between the cooling medium and the indoor air. Because it is closer to the server heat source inside the cabinet, the cooling efficiency of the cooling medium is higher.

The x-Cooling heat pipe backplane air conditioning unit adopts a modular design, consisting of a fan module, a heat exchanger module, and an electrical control module. It is installed on the rear door of the cabinet without occupying the effective space of the machine room. Through the action of the heat pipe backplane evaporator and the fan, the heat of the server cabinet is reasonably cooled and discharged. The x-Cooling heat pipe backplane air conditioning unit can provide 3~12kW of cooling capacity, with basic dimensions of 570*165*2150. It supports single/double coil configuration, power/gravity heat pipes, and can be matched with air-cooled, chilled water, and water-cooled cooling source equipment. At the same time, the unit can be used with a VRH composite multi-heat pipe natural cooling host.

Application Scenarios

Heat pipe backplane air conditioning is a technology product that improves energy and resource utilization efficiency. It is suitable for new data center machine rooms and energy-saving renovations of existing data centers. It can be used in small, medium, and large data centers. In high-density machine rooms, the multi-unit heat pipe backplane system serves as an effective supplement to conventional machine room air conditioning, efficiently solving the problems of "hot spots" and "hot zones" in the machine room.

Such as supercomputing centers, data centers, cloud computing centers, liquid-cooled data centers, and newly built data centers in government, education, banking, securities, insurance, communications, Internet of Things, transportation, and energy industries, including main engine rooms, high-density machine rooms, communication machine rooms, transmission machine rooms, aggregation machine rooms, 5G base stations, switching machine rooms, mobile machine rooms, computer rooms, and electronic information system machine rooms, etc.

Features and Value

Safe and reliable

▪ The system utilizes the temperature difference and phase-change heat transfer of environmentally friendly refrigerants. The environmentally friendly refrigerant is gaseous at room temperature, eliminating the risk of water entering the machine room.

▪ All-sensible heat exchange design, no condensate water is produced.

High efficiency and energy saving

▪ The heat pipe backplane is installed close to the heat source, resulting in extremely high heat exchange efficiency.

▪ The system relies on gravity circulation, without high-power moving parts such as compressors and water pumps, resulting in low energy consumption; the power circulation only requires a low-power refrigerant pump.

▪ Unit zone speed control, optional supply/return air temperature control, matching the corresponding load.

Does not occupy machine room space

▪ The heat pipe backplane adopts an integrated design with the cabinet, which can solve the problems of insufficient cooling capacity of traditional machine room air conditioners and limited future server expansion without occupying machine room space.

Easy installation and maintenance

▪ The system piping uses special flexible hoses for easy installation.

▪ The fan adopts a hot-swappable installation method, making maintenance convenient and quick.

Search

Search