Post Requirements

Post Requirements

- 1

- 1

Yamaha Engine Co., Ltd. was founded on July 1, 1955 and is a professional manufacturer of motorcycles. Since 1960, it has been producing motor boats, outboard engines, automobile engines, industrial automatic instruments, mounters, electric wheelchairs and other products.

Yamaha Engine Co., Ltd. is a company that has been among the world's top 500 many times. There are factories and operations all over the world. In 2006, it invested US$1 billion to establish "Japan Yamaha Engine Trading (Shanghai) Co., Ltd." in Zizhu Science Park in Minhang District. It mainly sells domestically made Yamaha series products overseas. Among them, in 2006, the research and development of "Yamaha Electric Bicycle" has been intensified and is sold in all provinces in the country.

With the continued success of Yamaha's motorcycle products, Yamaha Engine Co., Ltd. entered the manufacturing business of motor boats and outboard engines in 1960. After that, relying on engine and FRP technology, it continued to expand its business areas and move towards diversified business development. Today, Yamaha Engine Co., Ltd. not only operates the motorcycle business, but also operates a number of businesses including the boat business, power products business, automobile engine business, intelligent factory equipment business, aviation business and PAS business, thus extending its business areas from land to sea and even to the sky.

More than 40 years of performance is a strong proof of winning a high degree of trust.

Yamaha started its industrial robot business about 40 years ago. At one time, the business itself was faced with the crisis of being cancelled.

It has experienced several twists and turns to develop to this day.

Started starting a business with a strong lineup.

In December 1981, Yamaha Engine Co., Ltd. began the challenge of opening up new markets. This is an industrial robot. Yamaha has established the IM business unit and is preparing to launch the CAME (Computer Aided Manufacturing Equipment) robot developed for motorcycle production lines on the market.

The founding members of the IM business department focus on the technicians of the robot development team in the production technology department, and recruit outstanding technicians from outside, with a total of more than 50 people. Started starting a business with a strong lineup.

At that time, the mention of industrial robots naturally referred to large welding robots used in production lines such as automobiles. At that time, the CAME robot independently developed by IM was published on the cover of professional magazines with its miniaturized, high-functional, and cool design, which aroused considerable repercussions in the industry. But just eight months later, that day suddenly arrived.

The first product of the IM Division

"CAME (Computer Aided Manufacturing Equipment) robot"

The dissolution was announced in just eight months.

"Disband the IM business department"-Members of the business department were stunned by the executive officer's sudden announcement. In August 1982, the first IM career came to a short end.

One of the reasons for the dissolution of the IM business department was the fierce competition in the domestic motorcycle market, which was described by the world as the HY War (commercial war between Honda and Yamaha YAMAHA), which affected the company's operations. The fatal reason is that the robot products developed are not recognized by the market in terms of performance and cost performance, and their sales performance is poor. As a result, the IM business department once withdrew from the front desk. In the end, only 8 original IM members remained in the production technology department. Despite this, in order not to be ignored, we must not just wait like this.

It was also at that time that Tsuchiya Kazuhiko, who had been the director of the California R & D Center, returned to Japan and was appointed as the director of the technical department of the technical department. As soon as Tsuchiya returned to China, he began to look for seedlings of new business within the company. Facing Tsuchiya, the former IM member enthusiastically asked "I hope to continue the robot industry no matter what."

"I(always Isumo)M(problem Mondai)" cause.

"If it is a robot, the company has a technical foundation. It would be a pity to withdraw at this point." Tsuchiya's decision and the enthusiasm of the original IM members were finally intertwined. In July 1983, a "new" IM technical class in the Production Technology Department was quietly born. The IM technical class is located on the second floor of Hall 2 of Hamakubei Factory. It is a corner on the west side of the MC department. It can be said that it is under someone else's roof.

The IM technical class has been established, but we can't rest assured about it. "As long as we don't continue to make profits and may be disbanded at any time, we can only admit it." Everyone is always in a state of tension. IM members, who had no way out, worked overtime regardless of what they wanted. At best, they are enthusiastic about working, but from the perspective of company employees, they are a group of willful workaholics who only care about their own work. Unconsciously, IM has been dubbed "I(Always Isumo)M(Problem Mondai)" cause.

Despite this, IM members who were regarded as "problems" worked hard with the help of the tolerant factory atmosphere, and IM finally began to develop slowly.

All handmade exhibitions.

Freshman IM chose the "Tokyo International Robot Exhibition" as the stage for official public release to promote himself. The exhibition is expected to be held in September 1983. For the rebuilt IM technology class, there are only 2 months left before the exhibition. Working overtime every night until the eve of delivery, I finally prepared "robot-like products." At the exhibition venue, IM technicians were still assembling robot systems on the eve of the opening night and late into the night. It is said that even the patrolling security guards couldn't help but smile bitterly.

Of course, no one within IM has experience participating in an exhibition. For the establishment of the booth, the display boards and leaflets for product descriptions are all handmade. All product introductions during the exhibition are also handled by IM members themselves. It is simply incomparable to other booths with beautiful promotional models. Although they are not skilled enough, everyone has a heart that will never admit defeat in terms of enthusiasm and vitality.

A phone call that changed your destiny.

No robot was sold during the "Tokyo International Robot Show". However, not long after, a manufacturer called and said,"I was very interested in seeing Yamaha's robots at the exhibition." The order he put forward was "Can we make small mounters using the robotic technology on display?" Small mounters (now surface mounters) are devices that automatically mount electronic components on the surface of printed circuit boards. Nowadays, surface mounters are products with relatively good IM revenue. This phone call can be said to have greatly changed the fate of IM.

After that, IM actively participated in exhibitions. Even if Yamaha Engine's robots are not yet famous, the company's name is widely known. Opportunities for customers to come to the booth for negotiations are gradually increasing. Soon, they began to receive large orders for brake assembly lines and manufacturing systems for copiers.

Cooperate with well-known overseas companies

As the printed circuit board market continues to expand, the market demand for Yamaha's surface mounters also continues to increase. Braving strong headwinds, the newborn IM, who started the voyage like a human rowing, began to attract attention unknowingly. In February 1988, a supply agreement was officially signed with a well-known electronic product manufacturer and became the manufacturer's surface mounter supplier. This success has become the driving force for the further development of the IM business. It not only enables IM to manufacture products that surpass European and American markets, but also cultivates the international awareness of IM members and promotes technical capabilities to achieve high-performance, high-functionality, and high-quality levels.

The IM career, once referred to as a "problem child", has continued to develop steadily, and now it has been praised as a "top student".

The origin of the Yamaha brand is the surname of the company's founder, Shinami Yamaba (Yamaha). Due to his familiarity with Western science and technology since he was young, Yamaha initially repaired medical equipment and also repaired organs, which eventually led to the birth of the Yamaha brand. Out of confidence in its career prospects, Yamaha overcame all difficulties and founded Yamaha Organ Company. With its enterprising spirit, foresight and decisive style, Yamaha finally achieved success. These laid the foundation of the Yamaha brand and are also an important spiritual asset of the Yamaha Group today. Based on a good start, Yamaha has relied on its cutting-edge technology and superb craftsmanship to diversify investment in a wider range of products and services, and has gradually developed into a popular manufacturer around the world.

More than 30 years of performance, thus winning a high degree of trust.

Yamaha Engine Company began developing robots more than 30 years ago. Research and development began to use robots in the company's motorcycle production line. Since then, Yamaha industrial robots have been continuously supporting production equipment in various industries such as the assembly of electrical products, the handling of vehicle parts, and the manufacturing of large LCD panels. The long-term performance achieved through experience in market competition and continuous improvement and innovation is a strong proof of winning a high degree of trust.

Provide customers with peace of mind and win trust with products.

The management system that "integrates manufacturing, sales, and technology" ensures highly reliable product manufacturing. Manufacturing, sales, and technology communicate frequently face-to-face with each other, and through cross-department collaboration, they quickly meet customer requirements and provide immediate solutions to customer questions and issues. Technical leaders often accompany sales personnel to provide consulting services directly to customers.

The more opportunities you have to go deep into the manufacturing site, the more conducive it will be to the development of new products.

Technology development not only inherits Yamaha technology but also wins market demand

"Motor control technology" that is indispensable for precise and high-speed movements,"mechanical controller development technology" that passes strict evaluation benchmarks, and "signal processing technology" that can operate stably in strict environments...

These Yamaha technologies, which have been gradually established since their original development, have been continuously advanced to maturity and refinement, and have been highly praised in terms of rigidity, durability, operability, etc.

In order to accurately and quickly meet the diverse needs of customers, we have independently developed "core technology *". By accumulating this professional technical knowledge, we can achieve rapid product development and flexible product extension and expansion.

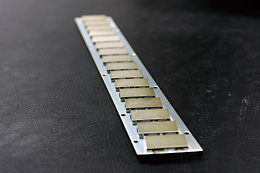

※Control circuit board, linear motor, linear scale (position detector), etc.

Yamaha quality that gives you peace of mind

The integrated quality assurance system formed by development, procurement, manufacturing, delivery, and after-sales service ensures product safety and reliability.

Key components are processed and produced within the company. Only robot manufacturers can carry out fine processing. Only through strict evaluation benchmark quality management can high-quality product manufacturing be achieved.

Have an evaluation system that ensures a high degree of reliability

In order to ensure the reliability of its products, Yamaha is committed to evaluating technology.

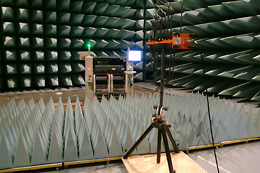

Evaluation tests were conducted on Yamaha Engine Company's equipment "anechoic chamber *" to establish an evaluation system for product development, thereby ensuring a high degree of reliability and quality.

※Anechoic chamber: It is an equipment prepared by Yamaha Group for the comprehensive development of EMC(Electromagnetic Wave Environmental Adaptability) technology for various products for the purpose of sharing within the group. International standards can be used as a benchmark to conduct adaptability evaluation tests of national standards.

Strict manufacturing process

Effectively use the management system that integrates manufacturing, sales, and technology in the manufacturing process. The series of processes of "inspection → processing → assembly → inspection → delivery" are completed throughout, so that customers can be provided with high-quality and low-priced products within a short delivery period.

Yamaha Engine Co., Ltd. has been in business for more than 50 years and has always insisted on achieving various value creation through product manufacturing and services. Yamaha Engine Co., Ltd.'s "corporate philosophy" consists of three major concepts and guidelines. The first is the significance of the company's existence, that is, the "corporate goal". The second is the basic attitude that should be possessed to achieve corporate goals, namely "business philosophy". Finally, there are the "action guidelines" that all employees need to keep in mind at all times. With the purpose of "providing people around the world with a touching and rich life", Yamaha Engine Co., Ltd. constantly uses wisdom and enthusiasm to realize people's dreams and create one touching after another that people expect, and always uses "touching" to create "Enterprise" as the corporate goal.

Search

Search