Post Requirements

Post Requirements

- 1

- 1

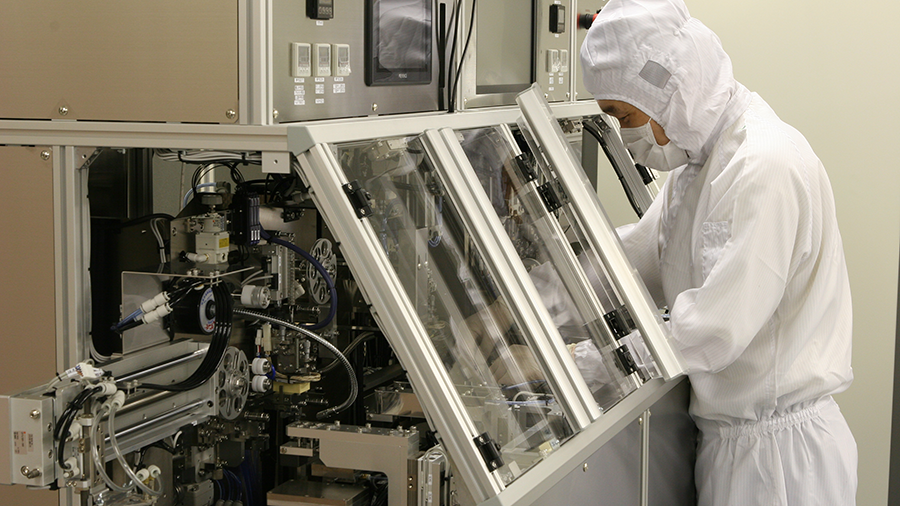

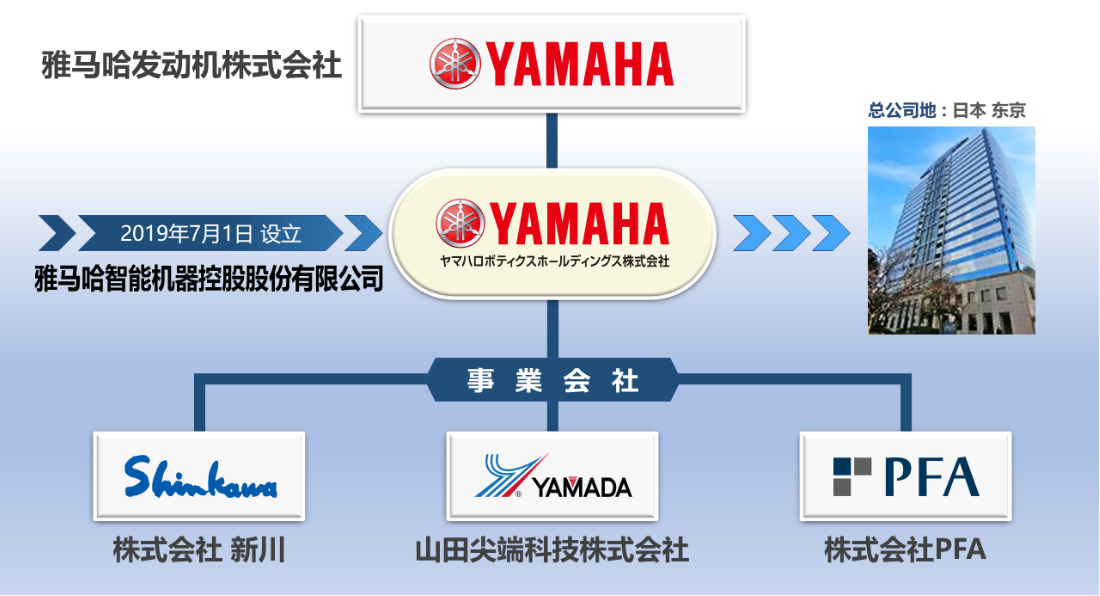

PFA is 100% invested by Yamaha Robot Holdings Co., Ltd. It was established on October 31, 1995, with a registered capital of 35.3 billion yen (yen), and its legal representative is Yoshinori Ijima. PFA has an extensive lineup of assembly and manufacturing equipment needed to "assemble" semiconductors, electronic components and other products. The equipment is used to produce camera modules, crystal devices and flat panel displays (FPDs). PFA also provides inspection and testing equipment to meet the need for unmanned and labor-saving operations. With its rich experience and technology in installation equipment, testing equipment, etc., as well as application capabilities, it is in a leading position in the field of crystal device and camera module manufacturing equipment. Based on the experience accumulated there, we provide production equipment not available so far with original ideas for new products such as high-brightness LEDs, MEMS, and FPD that are constantly emerging.

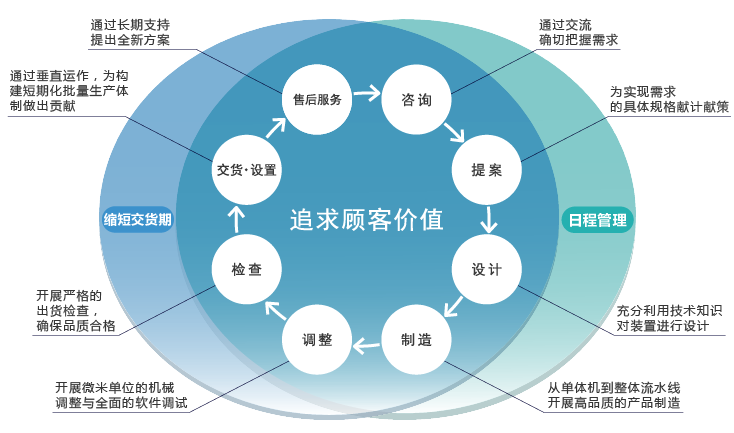

We increase productivity by providing reliable solutions Our policy is to think and solve with customers what is best for them through communication with them and to manufacture high-quality equipment that can be produced at the time of delivery. We consistently provide machine planning, design, manufacturing and after-sales services as partners in opening up the future with our customers. In addition, our company's strengths, speed and flexibility, will also challenge technological innovation in the future!

The electronics industry has unlimited possibilities, and creativity and speed are indispensable in growing markets where diverse needs continue to emerge. To achieve these things, reliable technical power and flexibility are necessary. PFA Co., Ltd., based on 40 years of factory automation experience, provides equipment and solutions that help customers 'careers from the standpoint of production technology. Always understand customers and "provide customers with new added value" is the basic attitude of PFA production. Launch products in a timely manner according to market conditions. PFA has rich experience, technology and application capabilities in practical installation, inspection equipment, etc. With these, it has a leading position in manufacturing equipment for quartz devices and camera modules. Based on these accumulated experience through continuous cultivation, we will use original concepts to provide unprecedented production equipment for these new products such as MEMS application products and new electronic components that have been launched one after another. In addition, we will continue to challenge technological innovation in the future by using the speed and flexibility that we are good at as weapons.

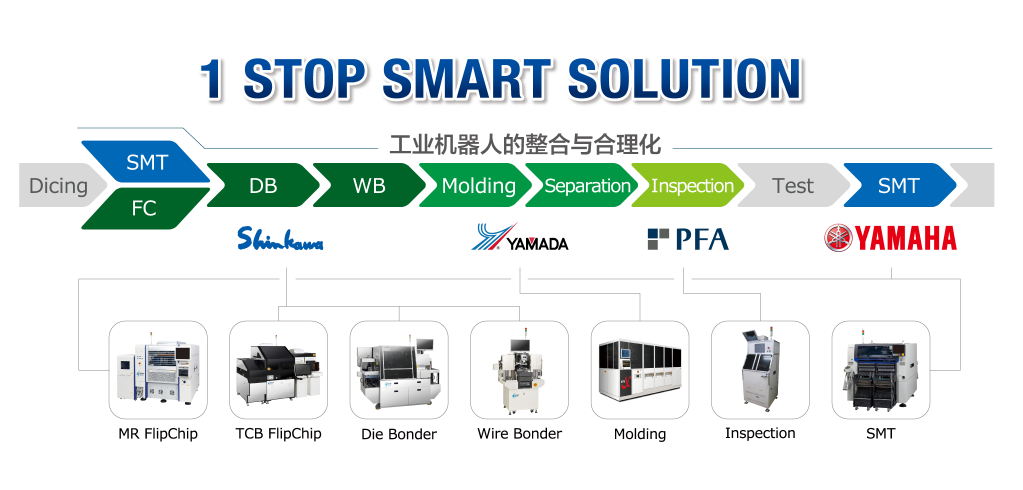

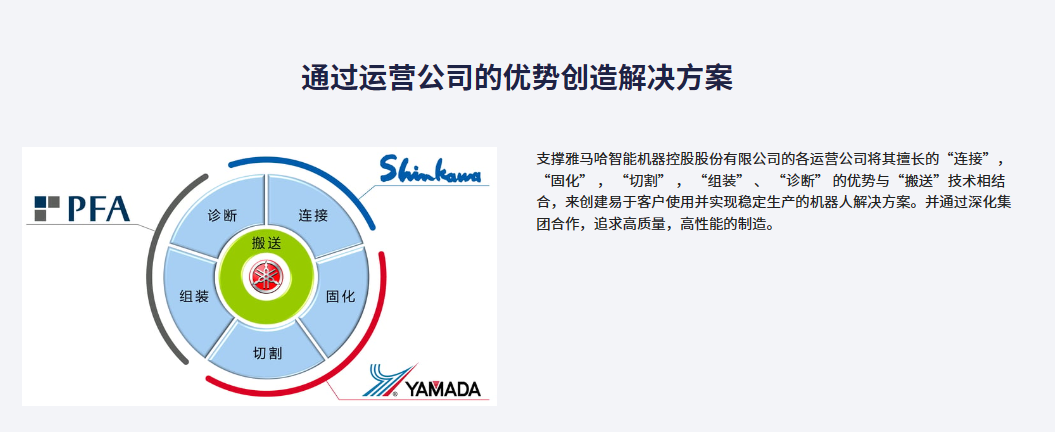

PFA is 100% invested by Yamaha Robot Holdings Co., Ltd. It operates jointly with Shinkawa Corporation, APIC Yamada Corporation and PFA Corporation, which develop, manufacture and sell semiconductor manufacturing equipment. Together with Yamaha Engine's surface mount process and industrial robot solutions, as a "total solution provider from Japan", it will meet the diverse needs of semiconductor and electronic component production. The operating companies supporting Yamaha Intelligent Machinery Holdings Co., Ltd. combine their strengths in "connection","solidification","cutting","assembly" and "diagnosis" with "transfer" technology to create a robot solution that is easy for customers to use and achieve stable production. And by deepening group cooperation, we pursue high-quality and high-performance manufacturing.

PFA has rich experience and technology in the field of crystal device manufacturing equipment and testing equipment. Moreover, by applying these experiences and technologies, PFA is a leader in crystal equipment and camera module production equipment. The know-how resulting from these achievements is used to develop production equipment full of original concepts to meet the needs of new products such as MEMS application products and new electronic components. In addition, we will continue to challenge technological innovation, leveraging our known advantages of speed and flexibility as our tools.

Search

Search