Post Requirements

Post Requirements

- 1

- 2

- 1

- 2

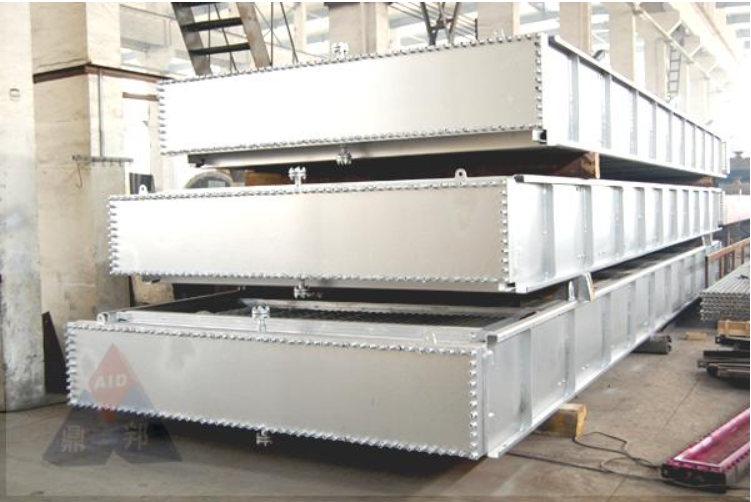

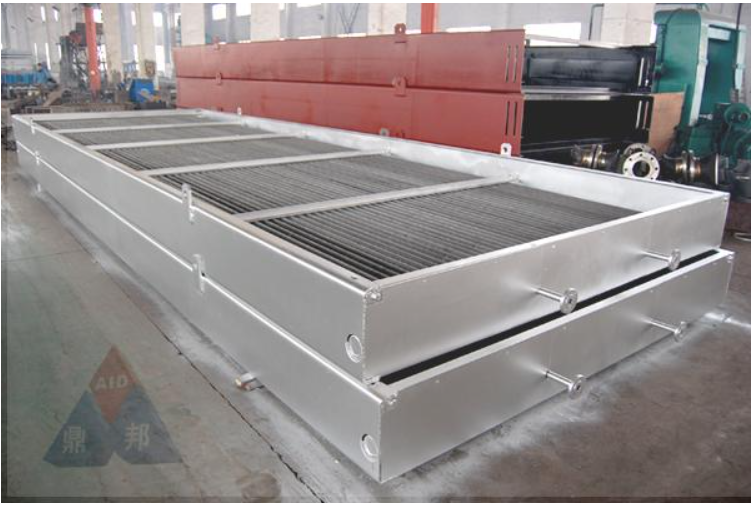

Wuxi Dingbang Heat Exchange Equipment Co., Ltd. has founded in 2003 and located in Anzhen Business District, Xishan District, Wuxi City, Wuxi Dingbang Heat Exchange Equipment Co., Ltd. has developed into a professional petrochemical equipment company integrating R&D, design, manufacturing and service after years of unremitting efforts, with an annual output value of more than 400 million yuan, and was successfully listed on the Beijing Stock Exchange on April 8, 2024 (stock code 872931). As a high-techenterprise, a "specialized, special and new" small and medium-sized enterprise and an innovative small and medium-sized enterprise in Jiangsu Province, Wuxi Dingbang focuses on the R&D, design, manufacturing and sales of heat exchange equipment, providing customers with stable and energy-saving professional heat exchange solutions. At present, the company has obtained 9 invention patents and 55 utility model patents. It holds A2 pressure vessel manufacturing license, A4 air-cooled heat exchanger safety registration certificate, ASME U steel seal authorization certificate and other qualification certifications, and establishes and implements ISO9001 quality management system, ISO14001 environmental management system, and ISO45001 occupational health and safety management system. It is the drafting unit of the enterprise standard "Radiographic Testing Technology and Rating Code for Pipe Tube Sheet Angle Joints" of China Petroleum & Chemical Corporation, a member of the Heat Exchanger Sub-Technical Committee of the National Boiler and Pressure Vessel Standardization Technical Committee, and a member of the Heat Exchanger Safety and Energy Efficiency Professional Committee of the China Technical Supervision and Information Association.

With its professional heat exchange equipment manufacturing capacity, high-quality product quality and service, Wuxi Dingbang has been widely recognized by large domestic enterprise groups such as Sinopec, PetroChina, CNOOC, Sinochem Group, Hengli Petrochemical, etc., and has established stable cooperative relations. At the same time, the company continues to improve its core competitiveness, and actively explore the international market, has been recognized and cooperated by Shell, ExxonMobil, Air Liquide and other large international enterprise groups.

In January 2003, Wuxi Dingbang Heat Exchange Equipment Co., Ltd. was established in Xishan District, Wuxi; During the period of 2003-2020, our company actively explored the market and reached cooperation with well-known domestic large petrochemical groups such as Sinopec and PetroChina. In 2020, we also became a supplier to foreign Shell companies; Participated in a benchmark project in January 2021- CNOOC Huizhou's annual production of 4.8 million tons of catalytic cracking unit, which is the largest single series catalytic cracking unit applied in China. In June of the same year, Sinopec Zhongke successfully put into operation the domestically produced refining and chemical integration project with the highest rate of domestication by using our company's slurry steam generator; On March 12, 2023, our company was rated as a specialized, refined, and innovative small and medium-sized enterprise in Jiangsu Province by the Department of Industry and Information Technology of Jiangsu Province; On March 12, 2023, leveraging the power of the capital market, a new stage of development was initiated and an IPO was held on the Beijing Stock Exchange.

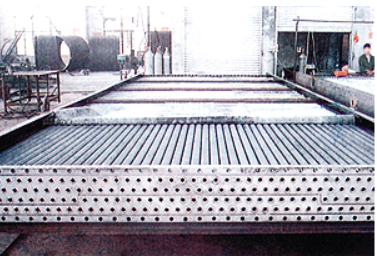

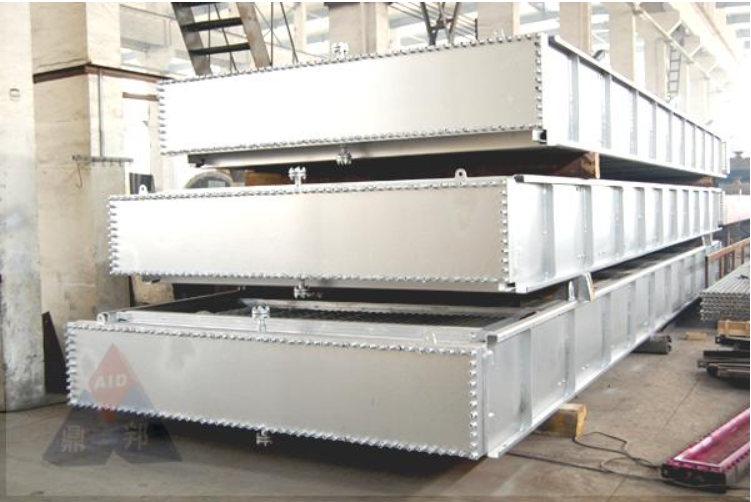

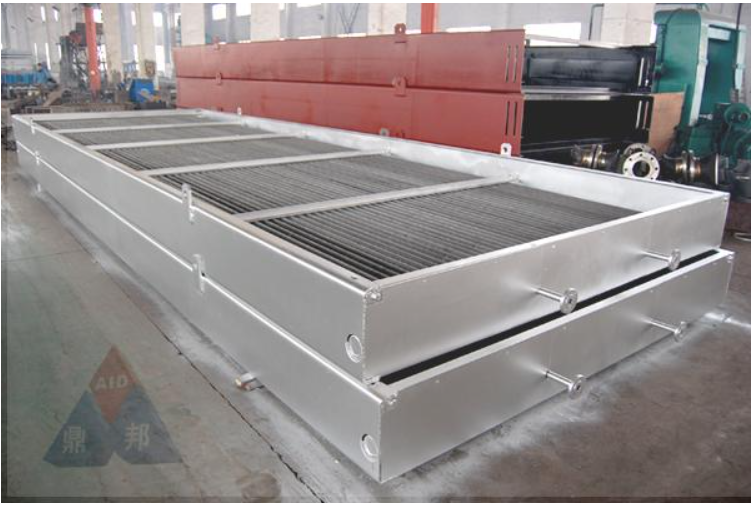

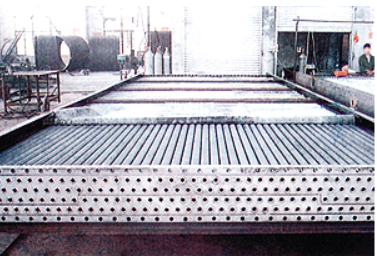

For a long time, the company has adhered to the development strategy of "double engines" in the domestic market and foreign markets, and "double kinetic energy" in technological innovation and operational innovation, focusing on the downstream industries of petrochemical industry and focusing on new heat exchange equipment to provide customers with stable and energy-saving professional and customized heat exchange solutions. Products include heat exchanger and air cooler, which are widely used in petrochemical industry and lead the industry trend in technology. The company has patented products with independent intellectual property rights, which are applied to the slurry steam generator in the catalytic device of refining and chemical enterprises. In 2013, it obtained the national invention patent certificate, and stood out among peers with its outstanding manufacturing performance. With the perfect and scientific manufacturing technology, not only the product performance is ensured, but also the service life of the equipment has reached the international and domestic leading level, and the domestic market share has reached more than 90%. Since May 26th, 2005, it has been officially authorized by Lummus Heat Transfer Company of the United States, which indicates Dingbang's leading position and international recognition in the field of heat exchange technology. HELIXCHANGER® heat exchanger has been used for more than 3,000 units in the world. Its technical innovation arranges sector baffles around the tube axis at different spiral angles to create spiral flow. This intelligent design greatly improves the performance, significantly reduces the vibration problem and ensures the safety of equipment use. After years of tempering and accumulation, the company has mastered a series of independent research and development professional technologies, and constantly expanded new multi-application scenarios. At present, it has obtained 9 invention patents and 55 utility model patents, and holds qualification certificates such as A2 pressure vessel manufacturing license, A4 air-cooled heat exchanger safety registration certificate, ASME U steel seal authorization certificate, etc., and has established and implemented various complete management systems.

Search

Search