Post Requirements

Post Requirements

- 1

- 1

Create a new model of digital assembly shop

Create a new benchmark for intelligent equipment manufacturing

Guoji Casting and Forging Machinery Co., LTD., affiliated to Guoji Group; In June 2018, the company entered Jinan Economic Development Zone, and the new contract signed that year increased by 500% compared with 2017, realized 24.22 million yuan in profits and taxes, the per capita output value exceeded 4.5 million yuan, and the cumulative investment was 230 million yuan. It is a leading enterprise of high-end CNC equipment in the economic development zone.

In March 2019, it was selected as the intelligent manufacturing demonstration enterprise of Shandong Province Industry and Information Technology Department, and the national major special "low-pressure casting of aluminum alloy cylinder head for cars" successfully passed the acceptance. The national major project of "Green Manufacturing System Integration" will build the world's first fully automatic sand box production line, subvert traditional manufacturing and increase efficiency by 10 times.

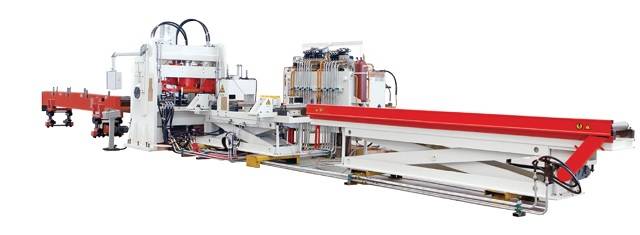

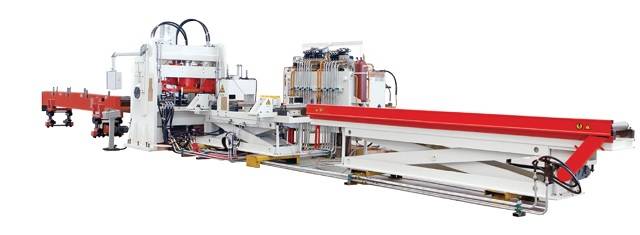

Static pressure molding line, international first-class, market share of more than 70%; Five hosts on three sides, domestic monopoly, the world's second, has an overwhelming advantage; Two-way bending production line, national invention patent, exclusive 100% market share; Intelligent manufacturing equipment for the whole industrial chain of commercial vehicle frames, independently developed and delivered in one station.

Guoji Casting and Forging, with high starting point positioning, high specification planning and high quality creation, is guided by the transformation of old and new momentum and high-quality development, integrating resources, continuously improving service quality and comprehensively breaking through innovation capabilities.

There are 129 middle and senior technology R&D personnel, 165 national patents, more than 500 high-tech research achievements, and 85 enterprise awards. Successfully passed the "three standards in one" certification and the EU CE certification; Static pressure line and three sides, won the "reform and opening up 40th anniversary outstanding product" title.

The "Digital assembly workshop" is the first demonstration project of the transformation of old and new kinetic energy with the practical application of intelligent interconnection technology.

Powerful industrial data center, cloud platform, big data MES management and ERP, BPM, PLM perfect integration, to achieve the design, procurement, assembly, commissioning and service of the whole process "blockchain" data management;

Intelligent security lighting system: real-time rapid response, smart watch alarm, timely processing, employee health dynamic reminder;

High-end intelligent tools: online job data matching, error correction, intelligent servo torque automatic calibration, high quality, high efficiency, high precision guarantee;

Intelligent logistics distribution: to achieve material management, assembly efficiency, multiple AGV cars intelligent optimization path, automatic avoidance, accurate delivery;

The whole paperless operation reduces 30,000 drawings per year, and the terminal station machine, mobile phone APP, tablet computer online review and visual management can achieve project progress, assembly quality, remote monitoring and real-time operation and maintenance without leaving the house.

The first phase of the digital assembly workshop project, the production efficiency is increased by 1.5 times, and the personnel is reduced by one-fifth.

Overall improvement in quality and efficiency: up to 270 type/hour of static pressure line productivity for a single host. Dual host static pressure line, the first set, zero breakthrough, efficiency increased by more than 30%. Five main engine three side impact, efficiency, accuracy comparable to the world giant Bilissoneng.

The brand and core competitiveness have been comprehensively improved, and the customers are all over the major automobile factories in China; And exported to Europe, South America, Southeast Asia, Africa and "One Belt and One Road" along more than 10 countries and regions.

"Internationalization, first-class, intelligent, standardized, efficient, humanized" national machine casting and forging, with intelligent interconnection digitalization and high-end equipment manufacturing efficient integration to promote the conversion of old and new momentum, to create the most innovative growth of high-tech enterprises, to contribute to Jinan intelligent equipment manufacturing 100 billion industry.

Search

Search