Post Requirements

Post Requirements

- 1

- 1

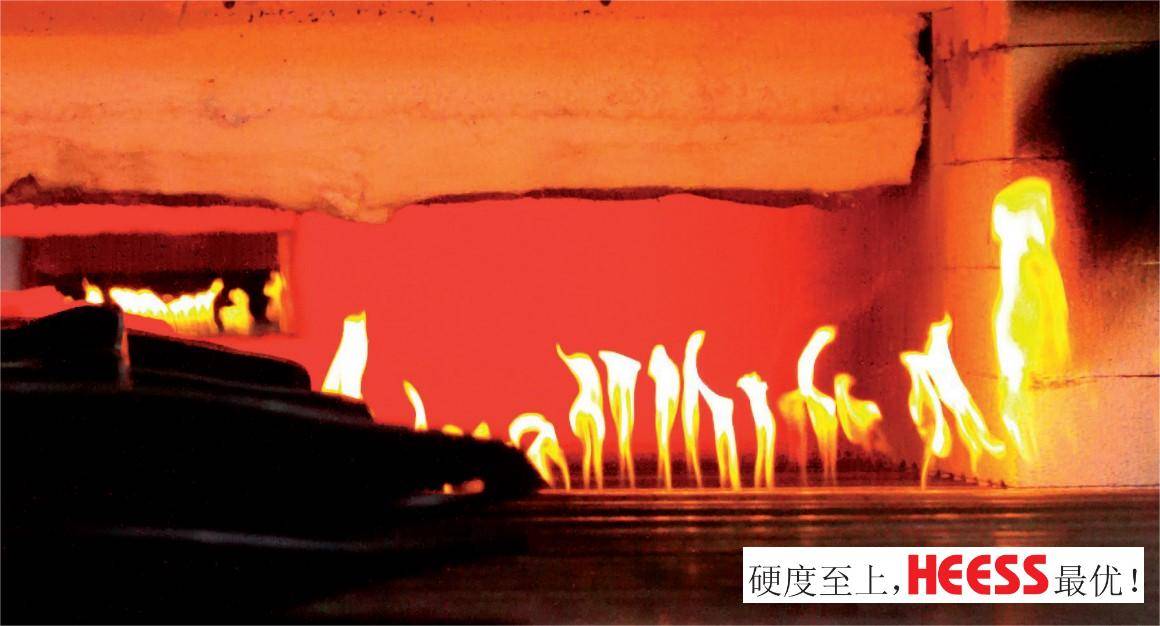

HEESS-Expert on Fixture Quenching Machines and Heat Treatment Operating Systems

HEESS was founded in 1945 and is located in Lampertheim, 50 kilometers south of Frankfurt, Germany, with approximately 90 employees. It is a world-renowned manufacturer specializing in the production of precision fixture quenching presses, providing automatic production lines from single-station manual feeding presses to multi-station press quenching. The fixture quenching press and tooling are developed, designed and manufactured by HEESS Company.

Globally, HEESS is far ahead in the research and development, engineering, production and heat treatment integration of fixture hardening machines. In response to the requirements of each customer's quenching process, HEESS adheres to the customer-first concept, continues to expand its business scope, and is committed to designing the best quenching solution for each customer. Most of the equipment provided by HEESS today is in fully automatic mode, with storage towers, furnace manipulators, conveyor belts, cleaners, automated handling units and fixture quench presses. All of the above equipment is controlled by PLC, that is, programmable logic controllers, workpiece tracking and operation panels. Customers can also purchase individual equipment based on their existing situation.

World-renowned automobile and gearbox manufacturers are using HEESS's fixture quenching equipment, which can reduce workpiece deformation during the quenching process, reduce scrap rates, reduce rework and shorten carburizing cycles, thereby obtaining better products and saving costs.

HEESS adheres to the people-oriented approach and regards the company's employees as its * precious asset. Mechanical and electrical engineers worked together to create approximately 300 systems, and systems created by HEESS can be found throughout quenching processes around the world. Its customers include Daimler, Chrysler, ZF, VW, Scania, BMW, MAN Eaton, Dana, Volvo, Hyundai, Fiat, Renault, and manufacturers serving the wind power industry Moventas and PSL. Users who have worked with HEESS for a long time have as many as 20 units of equipment provided by HEESS in their factories.

HEESS fixture quenching machine has been successfully used in the processing of precision components for large gearboxes of wind energy converters, marine engines, rail vehicles and engineering vehicles, as well as in the fields of bearing manufacturing, aviation and heat treatment contracting.

HEESS has many expertise in clamp press quenching processes and related operations in the field of heat treatment.

As a leader in heat treatment, HEESS provides you with more than 50 years of expertise!

HEESS has rich experience and a long history in the design and manufacturing of fixture quenching equipment. Cooperation with HEESS means ensuring quality.

Search

Search