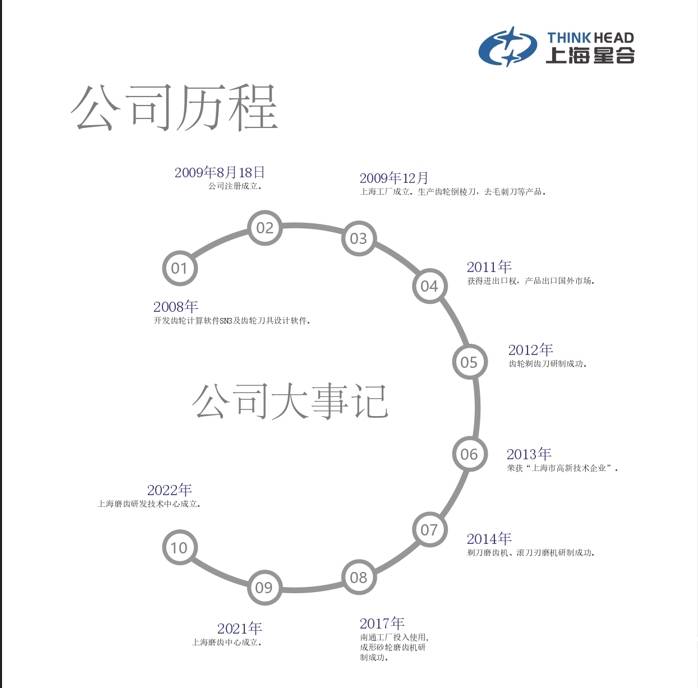

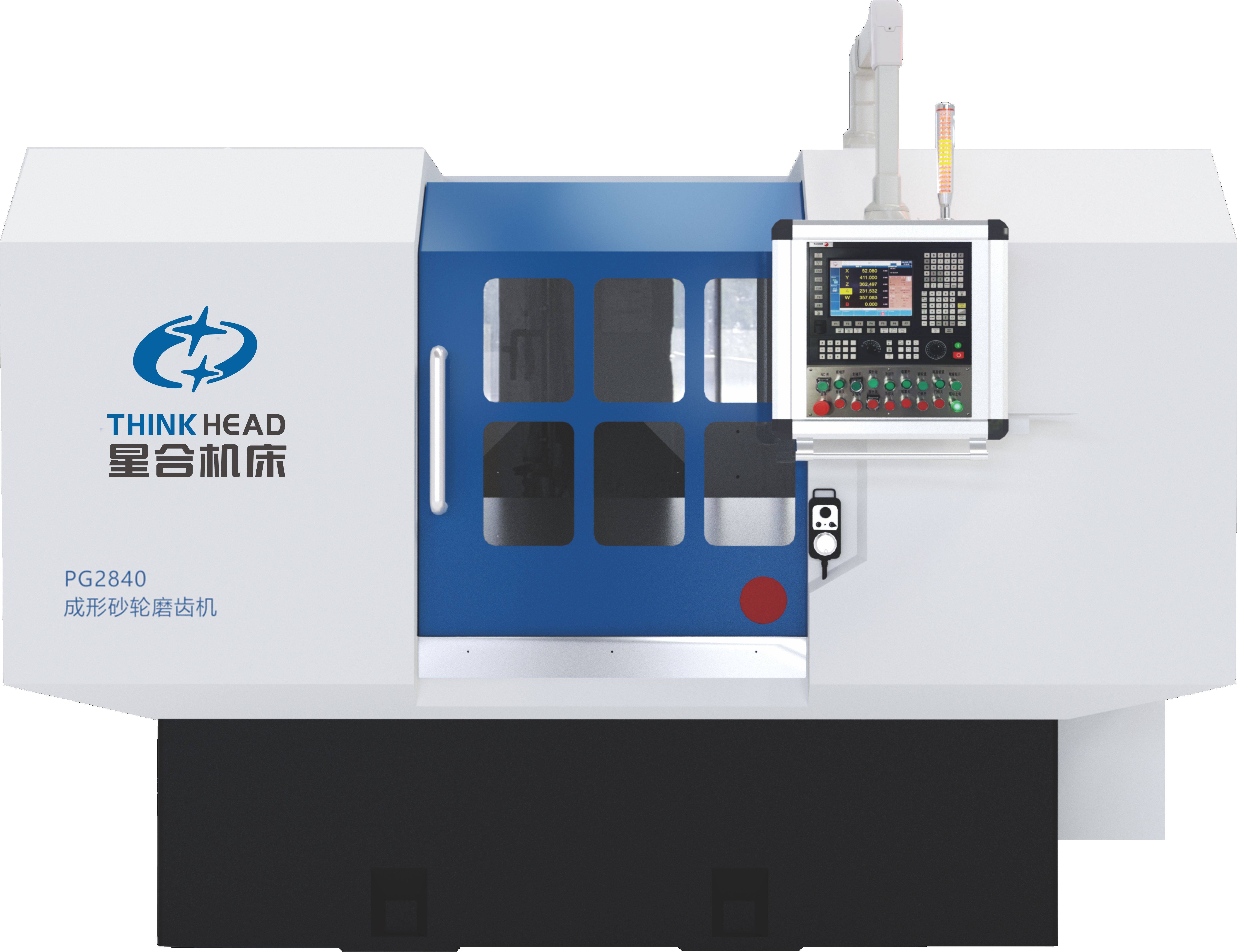

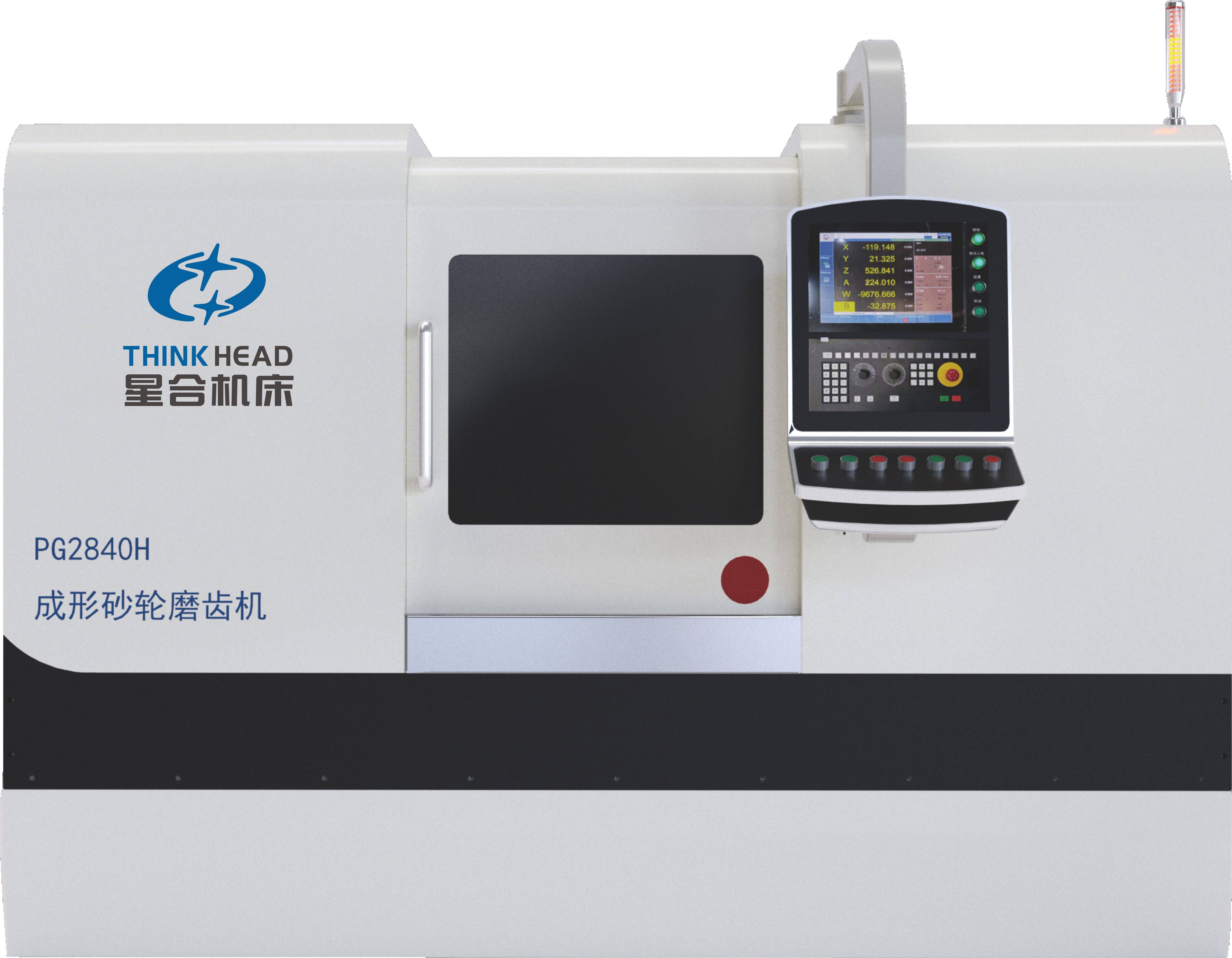

Shanghai Xinghe Electromechanical Co., Ltd. was established in 2009, committed to researching and manufacturing high-end CNC machine tools and cutting tools. Obtained dozens of patent authorizations and software copyrights for Shanghai's "specialized, refined, innovative" enterprises and high-tech enterprises. After years of dedicated research and development, Xinghe has mastered the core technologies of high-speed spindles, high-precision indexing heads, trimming axes, servo tailstock and other key components, and has mass produced them. Xinghe machine tools are widely used in industries such as automotive manufacturing, robotics, wind power, aerospace, precision reducers, etc. Xinghe has a gear grinding center and joint grinding laboratory in Shanghai, and a production base of tens of thousands of square meters in Nantong, Jiangsu. We have a constant temperature and humidity assembly workshop, a dust-free spindle room, and advanced processing equipment such as Nicolas gantry machining center and heavy-duty guide rail grinding. We also have advanced measuring instruments such as Klineberg detector and Zeiss coordinate system. Xinghe strives to create excellent machine tools and cutting tools for customers.

Post Requirements

Post Requirements

Search

Search