Post Requirements

Post Requirements

- 1

- 1

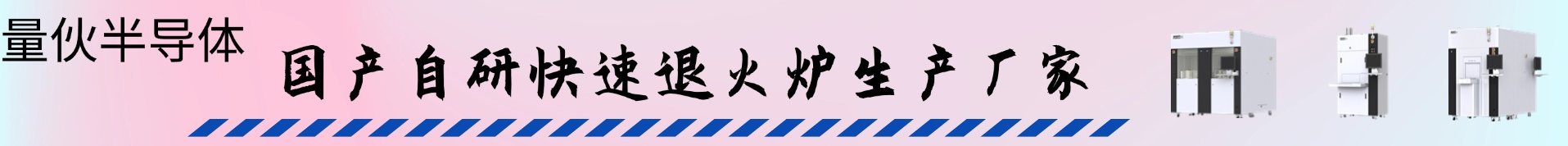

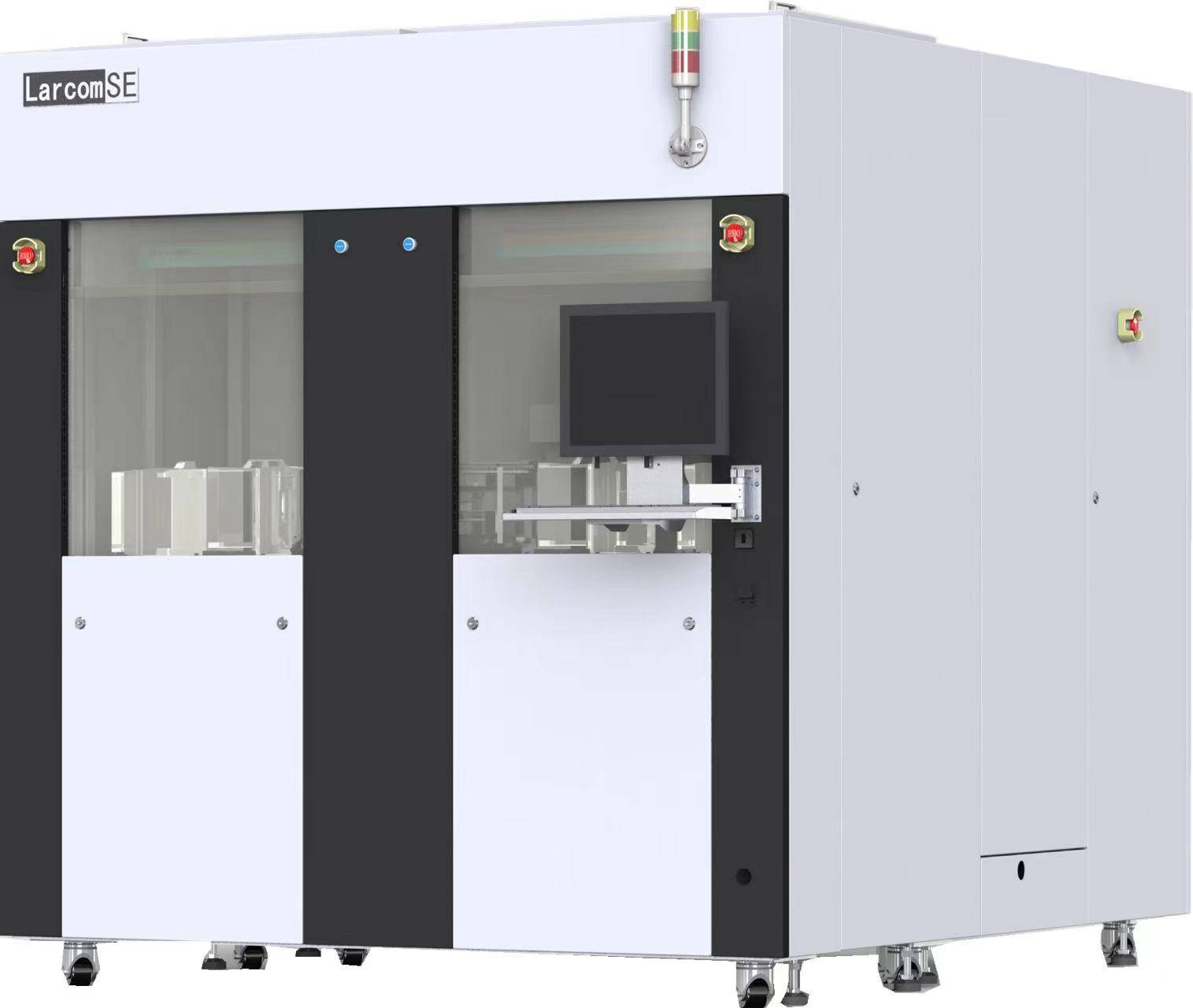

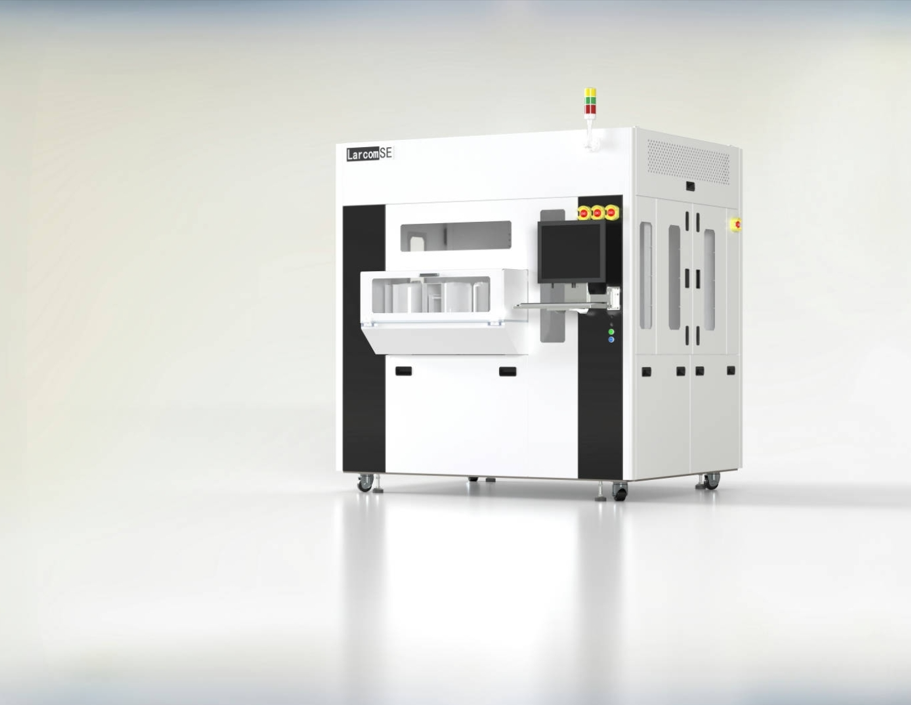

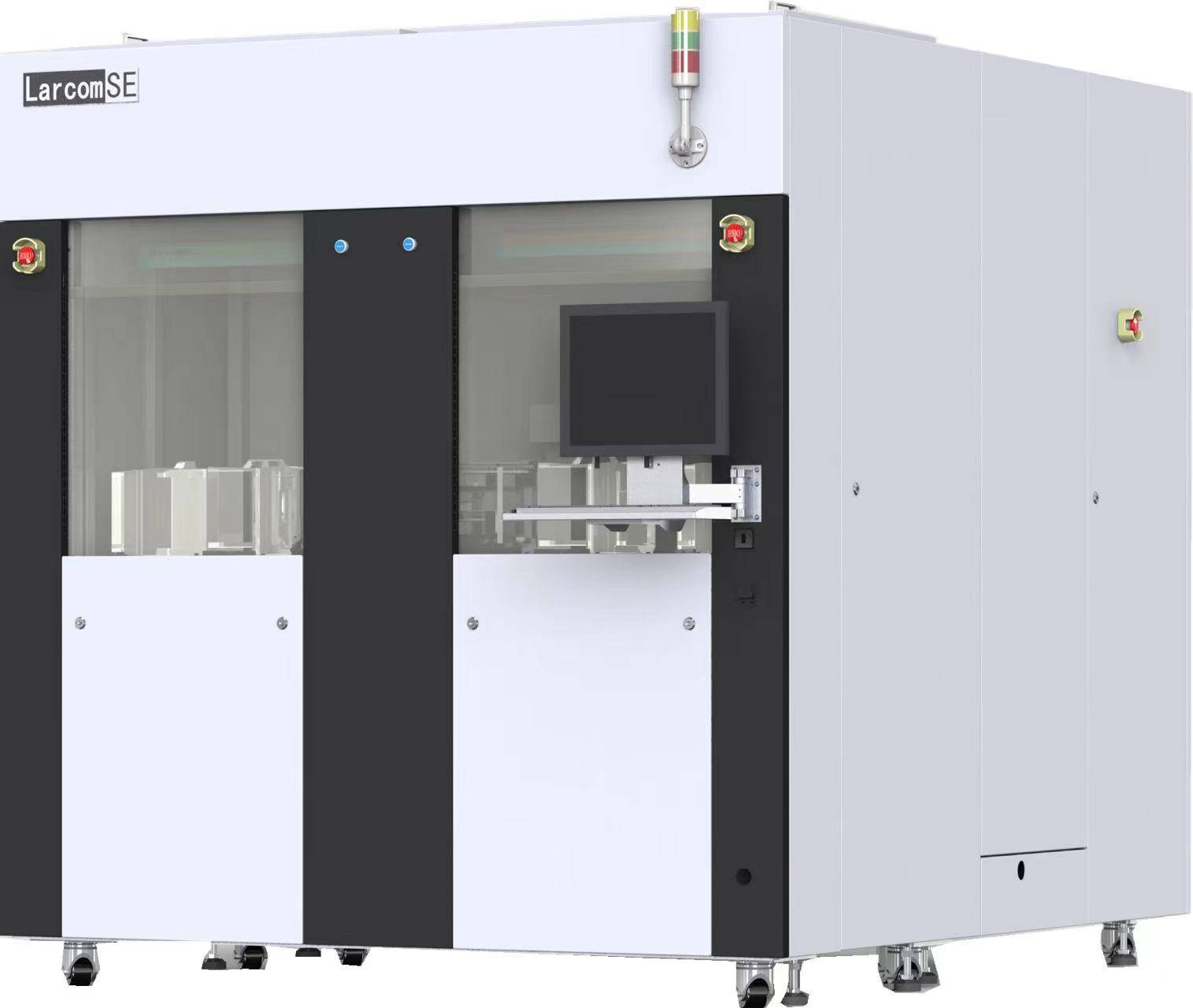

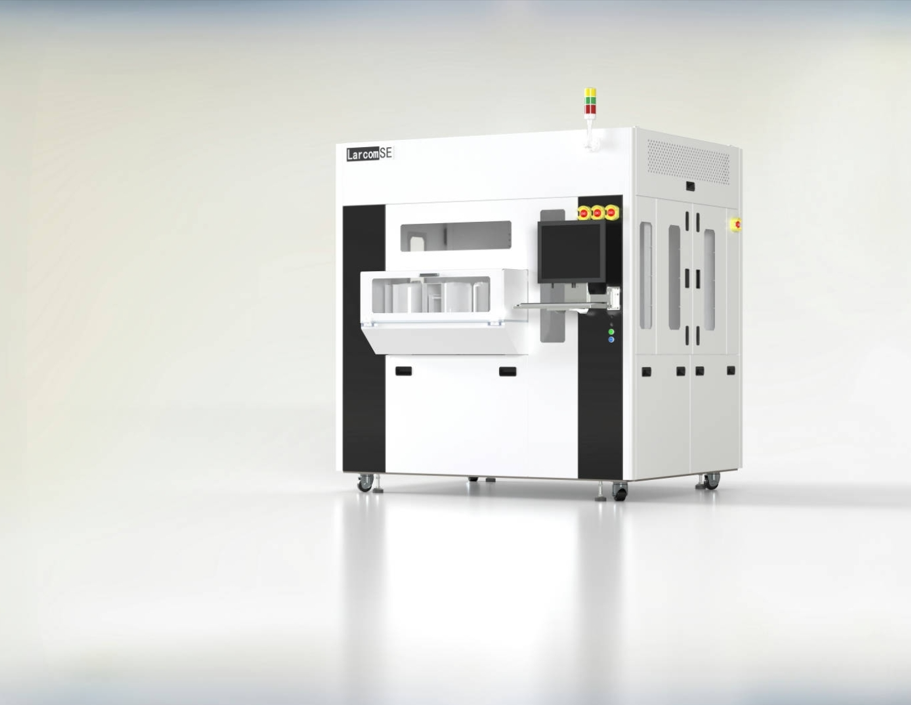

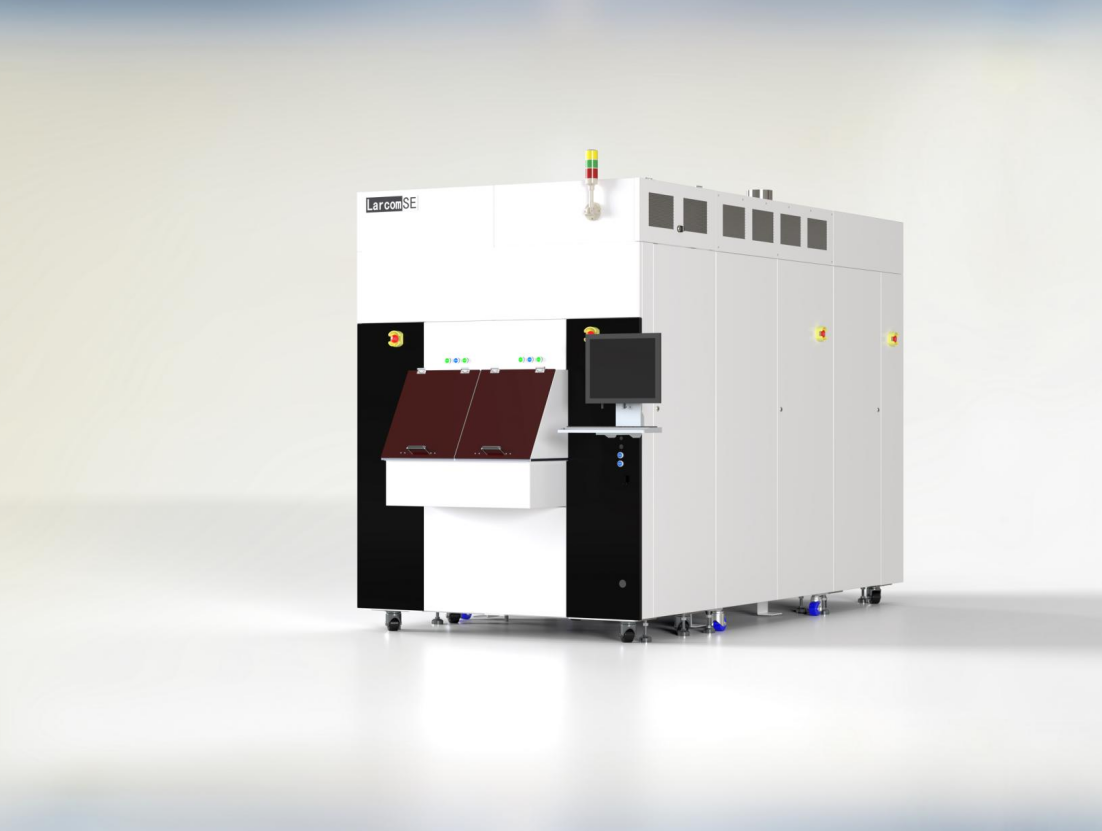

Larcom Semiconductor Equipment (Shanghai) Co., Ltd. was established in 2018, located in Pudong New Area, Shanghai, the most economically developed long corner area in China. The company is committed to semiconductor equipment, semiconductor equipment, high-end intelligent equipment research and development, design, manufacturing, sales and technical services, determined to provide more advanced domestic equipment for China's manufacturing industry! After years of efforts, the company has launched 6, 8, 12 inch rapid annealing furnace RTP equipment to the market, becoming the only professional supplier of RTP heat treatment equipment that can provide full-size series in China.

At present, Wangang Semiconductor Equipment (Shanghai) Co., Ltd. has a variety of intellectual property rights and software works, appearance, structure and other dozens of patents. It has obtained ISO9001 quality management system certification, ISO14001 environmental management system certification, ISO45001 occupational health and safety management system certification, AAA quality service integrity unit, AAA credit level certification, AAA credit level certificate, AAA contract-abiding and trustworthy unit, AAA credit report, and AAA credit supplier AAA integrity management demonstration unit, integrity entrepreneur certificate......

The company has established a joint laboratory with Beijing Institute of Technology, and has reached deep cooperation with Anhui University and Hefei Intelligent Robot Research Institute. It has R & D and manufacturing base in Hefei City, and technical service center in Beijing, Xi 'an and other places.

The management of the company has been engaged in the semiconductor equipment industry for more than 20 years, and has handled hundreds of equipment, familiar with the advantages and disadvantages of mainstream products, and accumulated rich experience in rapid heat treatment equipment technology and process. Since the establishment of Quantity Partner Semiconductor in 2018, it has rapidly launched 6-inch, 8-inch and 12-inch rapid annealing furnace equipment to the market. The fast annealing furnace RTP equipment independently developed by the company has the leading technical level in China, and the unique temperature control design concept and complex software algorithm meet the process requirements under more stringent conditions. It has been widely used in many IDM, Foundry, research institutes, universities, laboratories and other semiconductor production research units, and has also won the favor of customers in Europe and Asia.

Search

Search