Post Requirements

Post Requirements

- 1

- 1

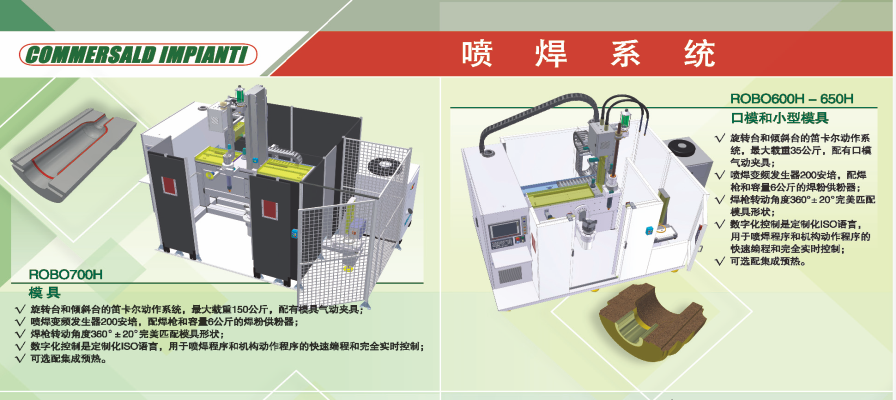

Italy's Commerseld plasma mold spray welding equipment meets the requirements of the vast industrial fields for welding process and quality. It controls welding parameters of different materials more flexibly and accurately, and the welding layer is more uniform, stable and firm. After years of research on automatic welding machines, we realized that only by applying plasma to arc welding technology to fully automatic welding machines can the welding process be more economical. The advent of automatic PTA units meets the requirements of welding process and quality in the vast industrial fields, ensuring low penetration, high metallurgical value and value-for-money ratio. An important difference between traditional welding and PTA plasma welding is the amount of welding powder consumed: fully automatic plasma-to-arc welding equipment consumes 40% less welding powder than traditional welding under high-speed deposition.

Founded in 1973, Italian Commerseld Impianti SRL is committed to developing PTA plasma spray welding technology, providing more high-performance, fully supporting and automated equipment to meet the technology and product needs of global glass mold companies and valve companies. The company provides a wide range of equipment, from PLC-controlled simple equipment to digitally controlled large-scale spray welding workstations. It can also be equipped with mold preheating and storage areas to achieve long-term automated operations with unmanned intervention. All installed equipment is equipped with remote assistance devices that can support unskilled welder operators. The company produces a variety of welding powders to further ensure the best results of spray welding.

Search

Search