发布需求

发布需求

发布需求

发布需求

商品详情

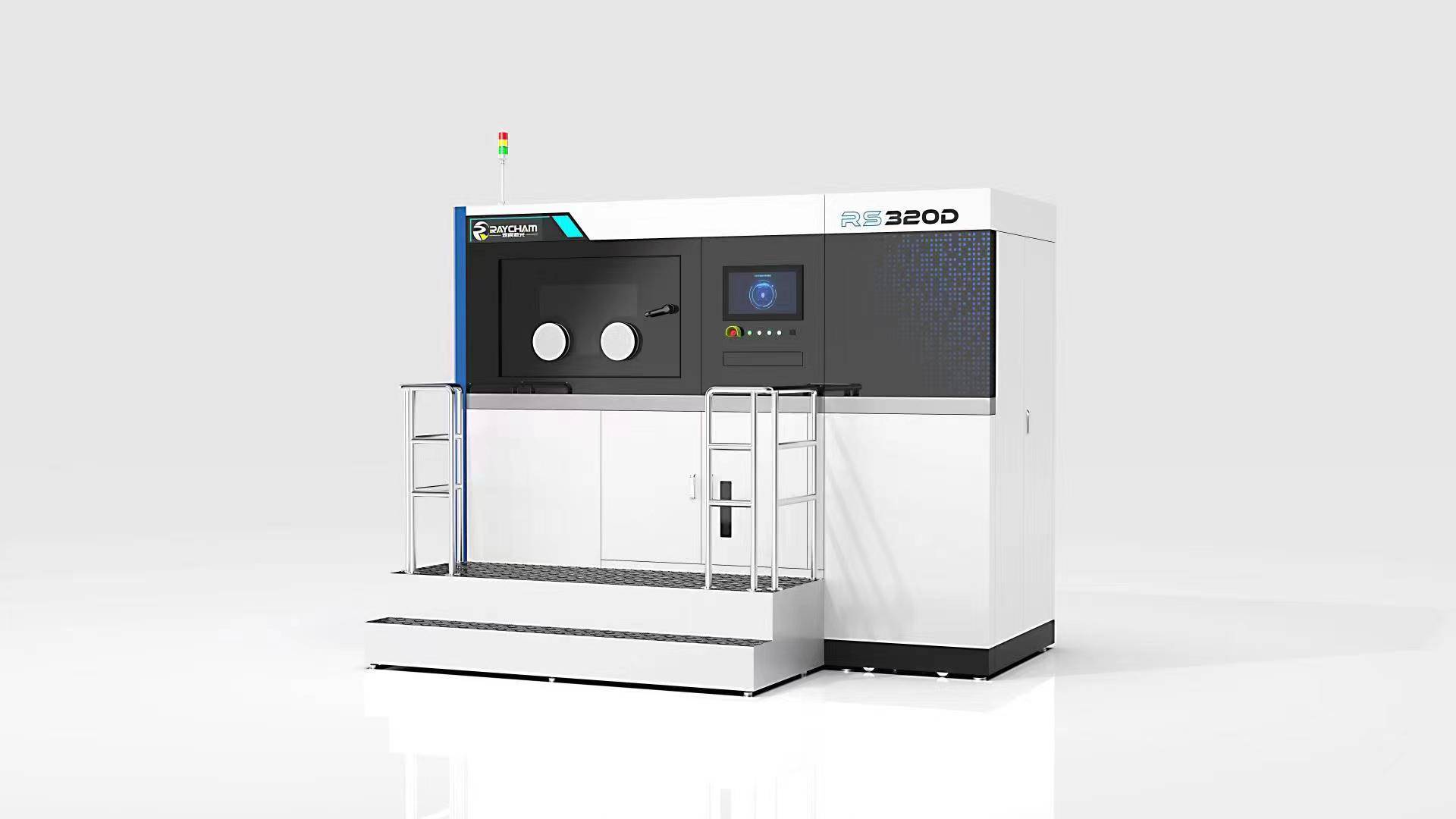

产品介绍

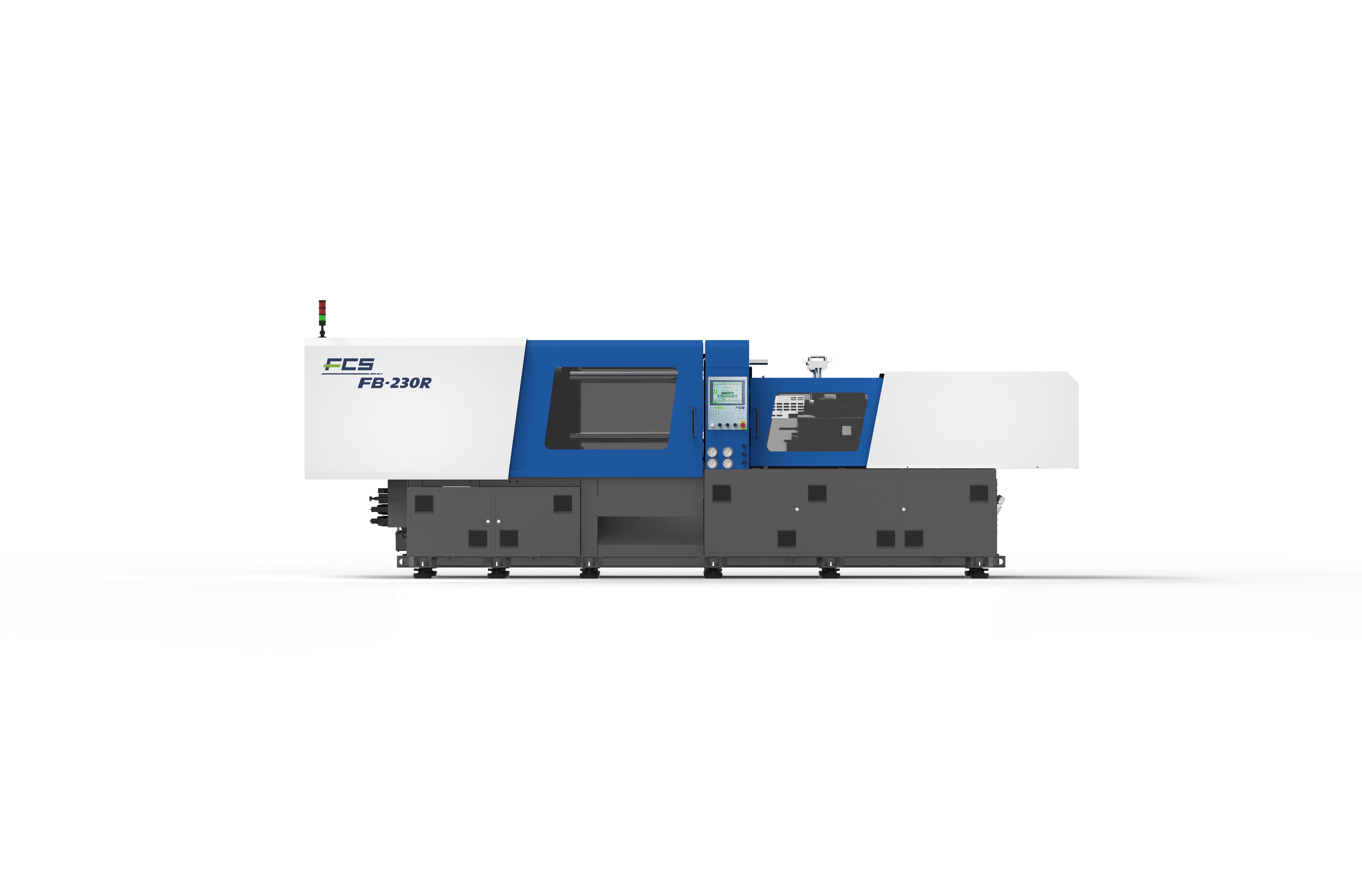

为FCS全新发表之外曲肘油压伺服节能机种,为专门生产薄壁包装的注塑机,锁模力涵盖220-500吨。

It is a newly-released servo hydraulic energy-saving model with outward toggle clamping unit, especially suitable for producing food container as well as food box, bubble teacup and bubble teacup lid. With its clamping force ranging from 220 tons to 500 tons.

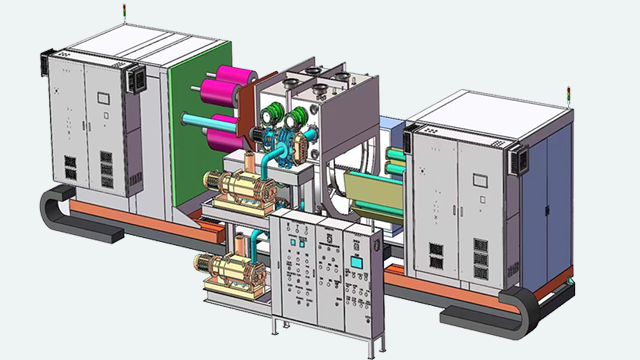

特点Characteristic:

高刚性模板设计,弹性变形小,成型锁模力更低。High rigidity platen mechanism, less deformation, lower clamping force.

标配高速比例阀,开模响应更快,定位更准,循环周期短。Standard high-speed proportional valve, with fast mold open response, accurate positioning and short cycle time.

整机管路采用无焊接工艺,降低漏油风险。The pipelines adopt no welding processing, decreasing the risk of oil leaking.

提升油路清洁度,机台寿命更长。Improving the cleanness of oil circuits and increase machine life.

标配KEBA控制系统。Standard equipped with KEBA control system.

动作扫描周期1ms以内。Operation mode scan within 1ms.

符合人体工程学布局。Data image monitoring.

标配红外奈米加热圈,升温快,保温性能好,节能超过30%。Standard infrared heater, fast heating, good heat preservation, energy saving over 30%.

采用PID温度控制,可控制在±1℃。Adopt PID temperature control, temperature control within ±1℃.

采用大L/D比,高混炼螺杆,塑化效果好。Adopt large L/D radio, high mixing screw and good plasticization efficiency.

注塑台及座移采用双线轨设计,摩擦阻力低,精度更高。The injection unit support adopts high-precision double linear guides, the lower friction resistance, the higher precision.

中惯量单缸注塑结构,起速快,重复精度高。The medium-inertia single-cylinder injection mechanism, fast response and high repeatability.

标配高性能伺服动力系统,节能约30%-70%。Equipped with high performance servo power system, energy saving about 30%-70%.

独特的模块化设计,方便维修。Unique modular design, easy maintainanece.

可选配双回路动作,最大程度缩短成型周期。Optional equipped with double loops system, improving production efficiency.

搜索

搜索