发布需求

发布需求

发布需求

发布需求

商品详情

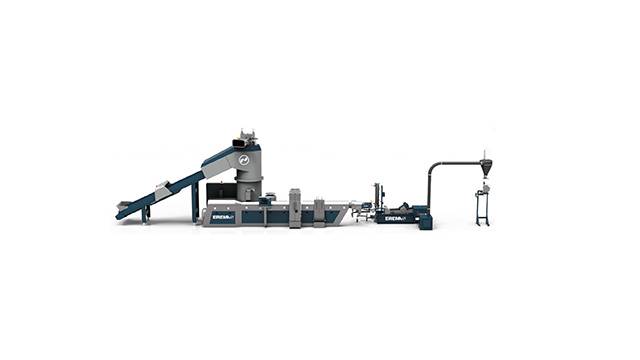

中大型塑件成型设备,适用于保险杆、仪表板等汽车产业、冷气压缩机外壳,甚至3000吨以上栈板专用等产品。锁模力涵盖500-4000吨。

It is medium and large-sized plastic parts molding equipment. It is applicable to automotive industry such as bumper and instrument panel, air-conditioner compressor housing, and even pallet over 3000 tons . With its clamping force ranging from 500 tons to 4,000 tons.

特点

本机种引进欧洲大厂设计,车壁结构钢性高,使用寿命长。

锁模机构短,可节省30%以上厂房空间。

开模行程及容模量大,适用的产品更为广泛,特别是深桶型产品。

锁模系统无肘节磨耗问题,故可减少润滑需求与维护成本。

注塑期间加压缸持续提供补压,使锁模力精确,达到误差值±1%内。

Characteristic

This machine has introduced the design of major companies in Europe. The wall structure has high rigidity with long service life.

Two-platen structure has shorter clamping unit which saves the factory space more than 30%.

The mold clamping stroke and capacity are bigger than traditional machines, making the machine suitable to produce more kinds of products especially plastic barrels with deep depth.

Clamping unit without toggle structure which reduces lubrication and maintenance cost.

During the injection, the pressurizing cylinder continues to provide compensating pressure, so that the clamping force is accurate, the error value is within ±1%.

搜索

搜索