发布需求

发布需求

发布需求

发布需求

商品详情

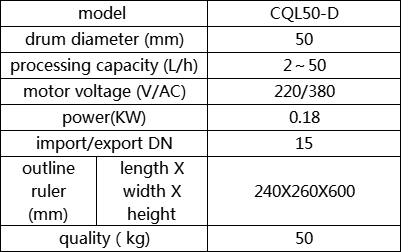

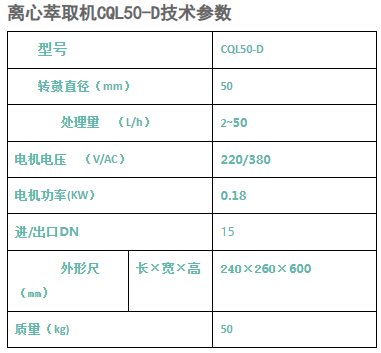

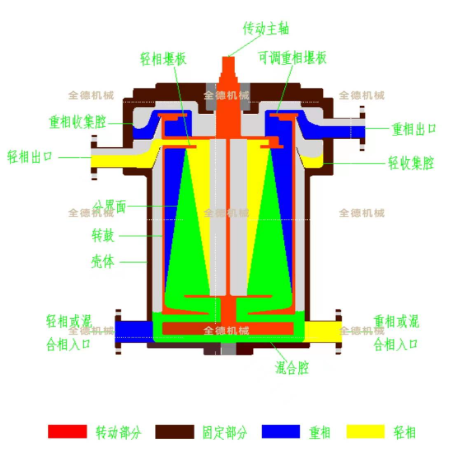

Principle of centrifugal extractor:

离心萃取机原理:

Principle of centrifugal extractor:

离心萃取机是利用离心力实现液液两相萃取、分离、混合传质、反应、洗涤等多功能设备。具有比重差(互不相融)的两相液借助离心力进行液液分离/萃取。由不融合的两相液分别进入离心萃取机内,通过旋转转子和混合叶轮进行充分混合,促使溶质转移,混合后吸入转子内部逐渐分离/萃取。分开的液相分别汇集到轻相重相的两收集腔并分别从出口排出。可以通过调换堰板和转速满足不同密度、不同粘度的物料。

Centrifugal extractor is a multi-functional equipment that realizes liquid-liquid two-phase extraction, separation, mixed mass transfer, reaction and washing by centrifugal force. Two-phase liquids with differential gravity (non-blending) are separated/extracted by centrifugal force. The non-fused two-phase liquid enters the centrifugal extractor respectively, and is fully mixed by rotating the rotor and mixing impeller to promote the transfer of solute. After mixing, it is sucked into the rotor to gradually separate/extract. The separated liquid phase is collected into two collecting cavities of the light phase and the heavy phase respectively and discharged from the outlet respectively. Materials of different densities and viscosities can be met by changing weir plates and rotating speeds.

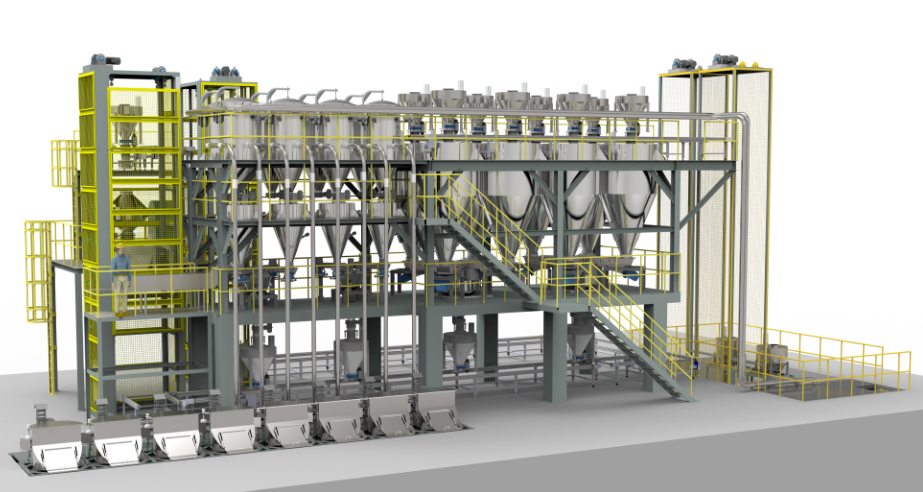

离心萃取/液-液分离工作原理(图示)

Centrifugal extraction/liquid-liquid separation working principle (Figure)

离心萃取机进行液液分离/萃取时将一种或多种溶质的溶液(图示蓝色)。具有密度差.不融合的溶液(图示黄色)进入设备混合腔。旋转转鼓和混合叶轮进行物料混合(图示绿色)。混合液吸入转鼓进行分相,旋转转鼓的离心力和物料的重力将重相(蓝色)分散到转鼓外侧,重相液从可调重相堰板溢流到重相收集腔并排出。轻相液(黄色)在转鼓内侧从轻相堰板溢流到轻相收集腔并排出。

A solution of one or more solutes (shown in blue) when a centrifugal extractor performs liquid-liquid separation/extraction. With a density difference, a non-fused solution (shown in yellow) enters the device mixing chamber. Rotate the drum and mixing impeller for material mixing (green). The mixture is sucked into the drum for phase separation, the centrifugal force of the drum and the gravity of the material disperse the heavy phase (blue) to the outside of the drum, and the heavy phase liquid overflows from the adjustable heavy phase weir plate to the heavy phase collection chamber and is discharged. The light phase liquid (yellow) spills from the light phase weir plate to the light phase collection chamber inside the drum.

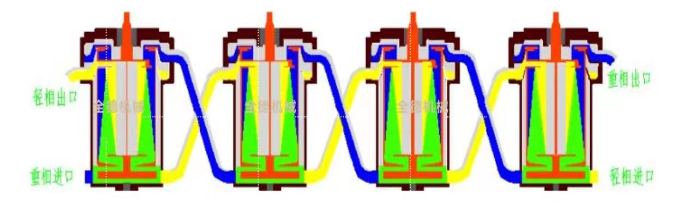

多级逆流萃取(图示)

Multistage countercurrent extraction (illustrated)

多级逆流实现多种物料的提取工艺,提取纯度,澄清度等。工艺简洁,萃取之间无需设泵,灵活增加级数达到更佳生产工艺要求。根据工艺要求,如:反应,洗涤,反萃等工艺直接在流程管道中增加或排出。

Multistage countercurrent to achieve a variety of materials extraction process, extraction purity, clarification and so on. The process is simple, no pump is required between extraction, and the number of stages is flexibly increased to achieve better production process requirements. According to the process requirements, such as: reaction, washing, stripping and other processes are directly added or discharged in the process pipe.

设备设计特点(优点):

Equipment design features (advantages):

1.立式直联电机驱动、结构简洁,维护保养简单,占地面积小

2.高转速,分相迅速,可分离密度差大于等于0.015

3.无基础安装,任意安放在相对水平对地面,楼面,平台即可

4.便于单级或多级串联逆流或错流洗涤、反应和萃取分离

5.适应性强,通过调换堰板和速度可满足不后密度、不同黏度的液体料液

6.机内容积小,节省萃取剂、溶剂或洗涤剂

7.全密闭运行,无泄漏,有利于防爆,有毒、有害,易挥发性等物料

8.调试简单快捷,变换工艺及物料时可快速调节堰板或调速改变离心力切换分相界面

9.多级串连使用中间无需设泵,任意增加萃取级数达到最佳萃取效果

10.运行平稳,自动化程度高,实现无人监控连续运行或间歇运行等优势特点

11.多种混合设计,根据物料性质选配,提高传质效率,可适用于剪切敏感乳化物料

12.GMP要求可选配在位清洗,适用于间歇性使用或更换物料交叉污

13.长径比大,转速高,分相彻底

14.无机械密封,无泄漏减少维护成本

15.低能耗,根据不同介质及流量选配

1. Vertical direct motor drive, simple structure, simple maintenance, small footprint

2. High speed, rapid phase separation, separation density difference is greater than or equal to 0.015

3. No foundation installation, arbitrarily placed on the relative horizontal ground, floor, platform can be

4. Convenient for single-stage or multistage series countercurrent or cross-flow washing, reaction and extraction separation

5. Strong adaptability, by changing the weir plate and speed can meet the density, different viscosity of the liquid liquid

6. The machine content is small, saving extractants, solvents or detergents

7. Fully closed operation, no leakage, conducive to explosion-proof, toxic, harmful, volatile and other materials

8. Debugging is simple and fast, when changing the process and materials, it can quickly adjust the weir plate or speed change the centrifugal force to switch the phase separation interface

9. There is no need to set the pump in the middle of the multi-stage series, and the extraction stage can be arbitrarily increased to achieve the best extraction effect

10. Smooth operation, high degree of automation, unmonitored continuous operation or intermittent operation and other advantages

11. A variety of mixed design, according to the nature of the material selection, improve the mass transfer efficiency, can be applied to shear sensitive emulsion materials

12.GMP requirements can be optional in-place cleaning, suitable for intermittent use or replacement of material cross contamination

13. Large length-diameter ratio, high speed, thorough phase separation

14. No mechanical seal, no leakage to reduce maintenance costs

15. Low energy consumption, according to different media and flow options

广泛应用:食品、制药、农化、冶金、工业废水、生物制药、生物工程、植物提取、精细化工、石油化工、环保化工……等行业。

Widely used: food, pharmaceutical, agrochemical, metallurgy, industrial wastewater, biopharmaceutical, biological engineering, plant extraction, fine chemical, petrochemical, environmental protection chemical...... And other industries.

搜索

搜索